Page 185 - Mechanical Engineer's Data Handbook

P. 185

MANUFACTURING TECHNOLOGY 173

~~

5.2 Turning

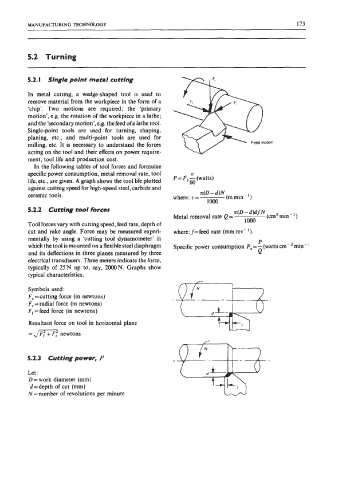

5.2. I Single point metal cutting

In metal cutting, a wedge-shaped tool is used to

remove material from the workpiece in the form of a

‘chip’. Two motions are required: the ‘primary

motion’, e.g. the rotation of the workpiece in a lathe;

and the ‘secondary motion’,e.g. the feed ofa lathe tool.

Single-point tools are used for turning, shaping,

planing, etc., and multi-point tools are used for

milling, etc. It is necessary to understand the forces

acting on the tool and their dects on power require-

ment, tool life and production cost.

In the following tables of tool forces and formulae

specific power consumption, metal removal rate, tool V

life, etc., are given. A graph shows the tool life plotted P = F, - (watts)

60

against cutting speed for high-speed steel, carbide and

ceramic tools. where: v= x(D -d)N (m min - ’ )

lo00

5.2.2 Cutting tool forces n(D-d)d fN

Metal removal rate Q = lo00 (an3 min-’)

Tool forces vary with cutting speed, feed rate, depth of

cut and rake angle. Force may be measured experi- where: f=feed rate (mm rev-’).

mentally by using a ‘cutting tool dynamometer’ in P

which the tool is mounted on a flexible steel diaphragm Specific power consumption P,=- (wattscrr-3 min-

and its deflections in three planes measured by three Q

electrical transducers. Three meters indicate the force,

typically of 25 N up to, say, 2000 N. Graphs show

typical characteristics.

Symbols used:

F, =cutting force (in newtons)

F, = radial force (in newtons)

F,=feed force (in newtons)

Resultant force on tool in horizontal plane

= Jm: newtons

5.2.3 Cutting power, P

Let:

D = work diameter (mm)

d-depth of cut (mm)

N = number of revolutions per minute