Page 187 - Mechanical Engineer's Data Handbook

P. 187

MANUFACTURING TECHNOLOGY 175

-

700

9 2400 ,t /

e

300

~

200-

100 -

I I I I I I

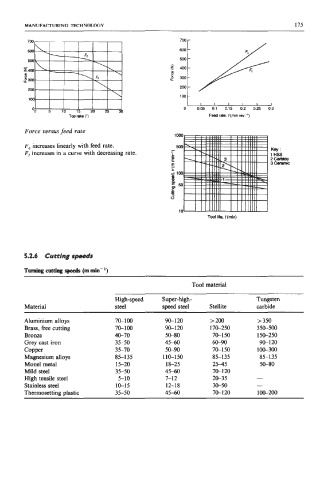

Force versus feed rate

F, increases linearly with feed rate.

Key:

F, increases in a curve with decreasing rate. 1 HSS

2cer#de

3comnic

Tool We, t (min)

5.2.6 Cutting speeds

Taming cllttiag speeds (mmia-')

Tool material

High-speed Super-high- Tungsten

Material steel speed steel Stellite carbide

Aluminium alloys 70-100 90-120 > 200 > 350

Brass, free cutting 70-100 90-120 170-250 350-500

Bronze 40-70 50-80 70-150 150-250

Grey cast iron 35-50 45-60 60 9CL120

Copper 35-70 50-90 70-150 100-300

Magnesium alloys 85-135 110-150 85-135 85-135

Monel metal 15-20 18-25 25-45 50-80

Mild steel 35-50 45-60 70-120

High tensile steel 5-10 7-12 20-35

Stainless steel 10-15 12-18 30-50 -

Thermosetting plastic 35-50 45-60 70-120 100-200