Page 188 - Mechanical Engineer's Data Handbook

P. 188

176 MECHANICAL ENGINEER’S DATA HANDBOOK

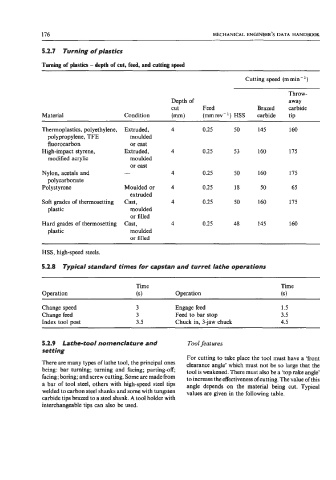

5.2.7 Turning of plastics

Turning of plastics - depth of cut, feed, and cutting sped

Cutting speed (m min- ’)

Throw-

Depth of away

cut Feed Brazed carbide

Material Condition (mm) (mm rev- ’) HSS carbide tip

Thermoplastics, polyethylene, Extruded, 4 0.25 50 145 160

polypropylene, TFE moulded

fluorocarbon or cast

High-impact styrene, Extruded, 4 0.25 53 160 175

modified acrylic moulded

or cast

Nylon, acetals and - 4 0.25 50 160 175

polycarbonate

Polystyrene Moulded or 4 0.25 18 50 65

extruded

Soft grades of thermosetting Cast, 4 0.25 50 160 175

plastic moulded

or filled

Hard grades of thermosetting Cast, 4 0.25 48 145 160

plastic moulded

or filled

HSS, high-speed steels.

5.2.8 Typical standard times for capstan and turret lathe operations

Time Time

Operation (s) Operation (SI

Change speed 3 Engage feed 1.5

Change feed 3 Feed to bar stop 3.5

Index tool post 3.5 Chuck in, 3-jaw chuck 4.5

5.2.9 Lathe-tool nomenclature and Tool features

setting

For cutting to take place the tool must have a ‘front

There are many types of lathe tool, the principal ones clearance angle’ which must not be so large that the

being: bar turning; turning and facing; parting-off tool is weakened. There must also be a ‘top rake angle’

facing; boring; and screw cutting. Some are made from to increase the effectiveness of cutting. The value of this

a bar of tool steel, others with high-speed steel tips angle depends on the material being cut. Typical

welded to carbon steel shanks and some with tungsten values are given in the following table.

carbide tips brazed to a steel shank. A tool holder with

interchangeable tips can also be used.