Page 186 - Mechanical Engineer's Data Handbook

P. 186

174 MECHANICAL ENGINEER’S DATA HANDBOOK

Typkd values of P.

Specific power

Material consumption, P.

Plain carbon steel 34

Alloy steel 71

Cast iron 24

Aluminium alloy 12

Brass 25

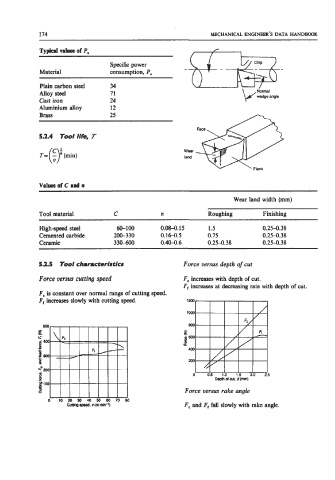

5.2.4 Tool life, T

Wear

T= - (min) lend

Values of C and n

Wear land width (mm)

Tool material C n Roughing Finishing

~~

High-speed steel &IO0 0.08-0.15 1.5 0.25-0.38

Cemented carbide 200-330 0.16-0.5 0.75 0.25-0.38

Ceramic 330-600 0.404.6 0.25-0.38 0.25-0.38

5.2.5 Tool ch8racteristics Force versus depth of cut

Force versus cutting speed F, increases with depth of cut.

F, increases at decreasing rate with depth of cut.

F, is constant over normal range of cutting speed.

F, increases slowly with cutting speed. 1200

lo00

i- 400

200

0 0.5 1.0 1.5 2.0 2.5

Wdcut. d(mm)

Force versus rake angle

F, and F, fall slowly with rake angle.