Page 190 - Mechanical Engineer's Data Handbook

P. 190

178 MECHANICAL ENGINEER’S DATA HANDBOOK

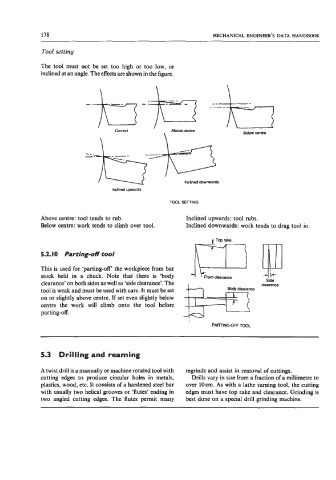

Tool setting

The tool must not be set too high or too low, or

inclined at an angle. The effects are shown in the figure.

\

Inclined downwards

Inclined upwards

TOOL SEl-rING

Above centre: tool tends to rub. Inclined upwards: tool rubs.

Below centre: work tends to climb over tool. Inclined downwards: work tends to drag tool in.

5.2. IO Parting-off tool

This is used for ‘parting-off the workpiece from bar

stock held in a chuck. Note that there is ‘body

Side

clearance’ on both sides as well as ‘side clea’rance’. The clearance

tool is weak and must be used with care. It must be set Body clearance

on or slightly above centre. If set even slightly below *3

centre the work will climb onto the tool before

parting-off.

PARTING-OFF TOOL

5.3 Drilling and reaming

A twist drill is a manually or machine rotated tool with regrinds and assist in removal of cuttings.

cutting edges to produce circular holes in metals, Drills vary in size from a fraction of a millimetre to

plastics, wood, etc. It consists of a hardened steel bar over 1Ocm. As with a lathe turning tool, the cutting

with usually two helical grooves or ‘flutes’ ending in edges must have top rake and clearance. Grinding is

two angled cutting edges. The flutes permit many best done on a special drill grinding machine.