Page 200 - Mechanical Engineer's Data Handbook

P. 200

188 MECHANICAL ENGINEER’S DATA HANDBOOK

Metal removal rate in milling

Metal removal rate

Material being cut (mm3 kW-’min-’)

Mild steel 18 900

Alloy steel 10 500

Cast steel 12 600

Grey cast iron 12 600

Stainless steel 8400

Copper 18900

Aluminium 42 OOO

Magnesium 42 OOO

Titanium 10 500

5.5 Grinding

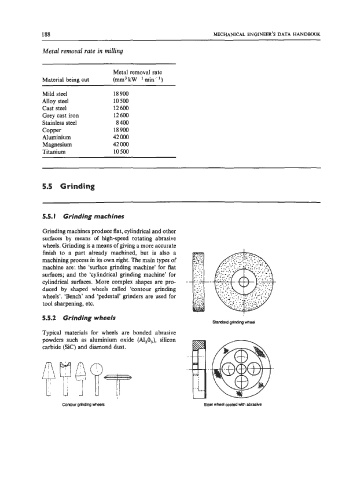

5.5. I Grinding machines

Grinding machines produce flat, cylindrical and other

surfaces by means of high-speed rotating abrasive

wheels. Grinding is a means of giving a more accurate

finish to a part already machined, but is also a

machining process in its own right. The main types of

machine are: the ‘surface grinding machine’ for flat

surfaces; and the ‘cylindrical grinding machine’ for

cylindrical surfaces. More complex shapes are pro- -

duced by shaped wheels called ‘contour grinding

wheels’. ‘Bench’ and ‘pedestal’ grinders are used for . .-

tool sharpening, etc.

5.5.2 Grinding wheels

Standard grinding wheel

Typical materials for wheels are bonded abrasive

powders such as aluminium oxide (A1203), silicon

carbide (Sic) and diamond dust.

Contour grinding wheels Steel Heel coated with abrasive