Page 58 - Mechanical Engineer's Data Handbook

P. 58

STRENGTHS OF MATERIALS 47

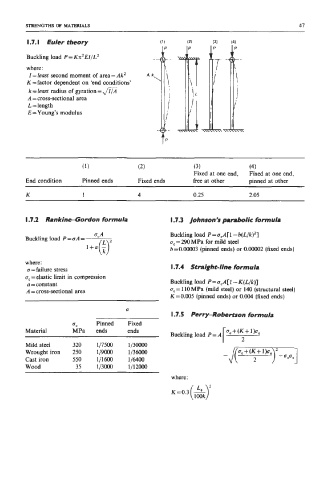

I .7. I Euler theory

Buckling load P=Kn2EIJL2

where:

I = least second moment of area = Ak2 A, k,

K = factor dependent on ‘end conditions’

k = least radius of gyration =

A = cross-sectional area

L = length

E =Young’s modulus

-4

1

(1) (2) (3) (4)

Fixed at one end, Fixed at one end,

End condition Pinned ends Fixed ends free at other pinned at other

K 1 4 0.25 2.05

I .7.2 Rankine-Gordon formula I .7.3 Johnson’s parabolic formula

OCA Buckling load P=a,ACl -b(L/k)21

Buckling load P = aA = a, = 290 MPa for mild steel

Ita(:)’ b=0.00003 (pinned ends) or O.ooOo2 (fixed ends)

where:

c = failure stress I .7.4 Straight-line formula

a, =elastic limit in compression

a =constant Buckling load P = a,A[ 1 - K(L/k)]

A =cross-sectional area a, = 110 MPa (mild steel) or 140 (structural steel)

K=0.005 (pinned ends) or 0.004 (fixed ends)

a

I .7.5 Perry-Robertson formula

DE Pinned Fixed

Material MPa ends ends

Buckling load P = A P+(:+l)ae

Mild steel 320 1/7500 1/3oooO

Wrought iron 250 1/9ooo 1/36000

Cast iron 550 1/1600 1/6400

wood 35 1/3000 1/12000

where:

K =0.3 (