Page 446 - Mechanical Engineers' Handbook (Volume 2)

P. 446

12 Hardware and Software for Digital Control 437

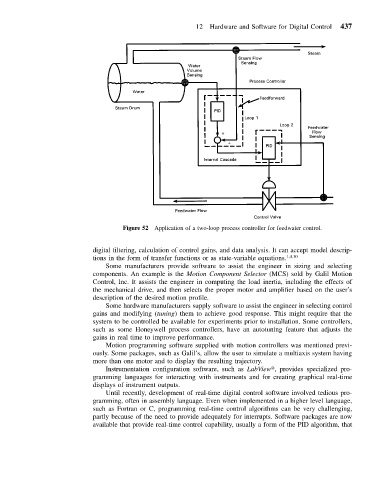

Figure 52 Application of a two-loop process controller for feedwater control.

digital filtering, calculation of control gains, and data analysis. It can accept model descrip-

tions in the form of transfer functions or as state-variable equations. 1,4,10

Some manufacturers provide software to assist the engineer in sizing and selecting

components. An example is the Motion Component Selector (MCS) sold by Galil Motion

Control, Inc. It assists the engineer in computing the load inertia, including the effects of

the mechanical drive, and then selects the proper motor and amplifier based on the user’s

description of the desired motion profile.

Some hardware manufacturers supply software to assist the engineer in selecting control

gains and modifying (tuning) them to achieve good response. This might require that the

system to be controlled be available for experiments prior to installation. Some controllers,

such as some Honeywell process controllers, have an autotuning feature that adjusts the

gains in real time to improve performance.

Motion programming software supplied with motion controllers was mentioned previ-

ously. Some packages, such as Galil’s, allow the user to simulate a multiaxis system having

more than one motor and to display the resulting trajectory.

Instrumentation configuration software, such as LabView , provides specialized pro-

gramming languages for interacting with instruments and for creating graphical real-time

displays of instrument outputs.

Until recently, development of real-time digital control software involved tedious pro-

gramming, often in assembly language. Even when implemented in a higher level language,

such as Fortran or C, programming real-time control algorithms can be very challenging,

partly because of the need to provide adequately for interrupts. Software packages are now

available that provide real-time control capability, usually a form of the PID algorithm, that