Page 553 - Mechanical Engineers' Handbook (Volume 2)

P. 553

544 Servoactuators for Closed-Loop Control

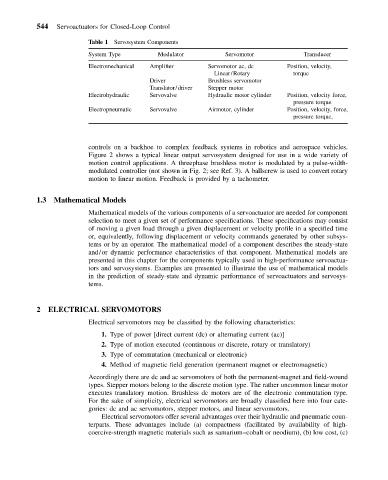

Table 1 Servosystem Components

System Type Modulator Servomotor Transducer

Electromechanical Amplifier Servomotor ac, dc Position, velocity,

Linear/Rotary torque

Driver Brushless servomotor

Translator/driver Stepper motor

Electrohydraulic Servovalve Hydraulic motor cylinder Position, velocity force,

pressure torque

Electropneumatic Servovalve Airmotor, cylinder Position, velocity, force,

pressure torque,

controls on a backhoe to complex feedback systems in robotics and aerospace vehicles.

Figure 2 shows a typical linear output servosystem designed for use in a wide variety of

motion control applications. A threephase brushless motor is modulated by a pulse-width-

modulated controller (not shown in Fig. 2; see Ref. 3). A ballscrew is used to convert rotary

motion to linear motion. Feedback is provided by a tachometer.

1.3 Mathematical Models

Mathematical models of the various components of a servoactuator are needed for component

selection to meet a given set of performance specifications. These specifications may consist

of moving a given load through a given displacement or velocity profile in a specified time

or, equivalently, following displacement or velocity commands generated by other subsys-

tems or by an operator. The mathematical model of a component describes the steady-state

and/or dynamic performance characteristics of that component. Mathematical models are

presented in this chapter for the components typically used in high-performance servoactua-

tors and servosystems. Examples are presented to illustrate the use of mathematical models

in the prediction of steady-state and dynamic performance of servoactuators and servosys-

tems.

2 ELECTRICAL SERVOMOTORS

Electrical servomotors may be classified by the following characteristics:

1. Type of power [direct current (dc) or alternating current (ac)]

2. Type of motion executed (continuous or discrete, rotary or translatory)

3. Type of commutation (mechanical or electronic)

4. Method of magnetic field generation (permanent magnet or electromagnetic)

Accordingly there are dc and ac servomotors of both the permanent-magnet and field-wound

types. Stepper motors belong to the discrete motion type. The rather uncommon linear motor

executes translatory motion. Brushless dc motors are of the electronic commutation type.

For the sake of simplicity, electrical servomotors are broadly classified here into four cate-

gories: dc and ac servomotors, stepper motors, and linear servomotors.

Electrical servomotors offer several advantages over their hydraulic and pneumatic coun-

terparts. These advantages include (a) compactness (facilitated by availability of high-

coercive-strength magnetic materials such as samarium–cobalt or neodium), (b) low cost, (c)