Page 437 - Mechanical Engineers' Handbook (Volume 4)

P. 437

426 Refrigeration

perature low enough to avoid overheating of the compressor and improves compression

efficiency.

Compound compression with economizers also affords the opportunity to provide re-

frigeration at an intermediate temperature. This provides a further thermodynamic efficiency

gain because some of the refrigeration is accomplished at a higher temperature, and less

refrigerant must be handled by the lower-temperature stages. This reduces the power con-

sumption and the size of the lower stages of compression.

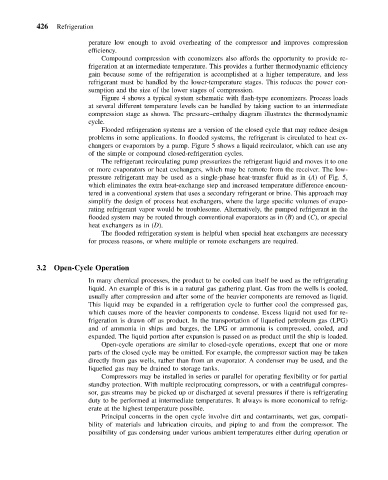

Figure 4 shows a typical system schematic with flash-type economizers. Process loads

at several different temperature levels can be handled by taking suction to an intermediate

compression stage as shown. The pressure–enthalpy diagram illustrates the thermodynamic

cycle.

Flooded refrigeration systems are a version of the closed cycle that may reduce design

problems in some applications. In flooded systems, the refrigerant is circulated to heat ex-

changers or evaporators by a pump. Figure 5 shows a liquid recirculator, which can use any

of the simple or compound closed-refrigeration cycles.

The refrigerant recirculating pump pressurizes the refrigerant liquid and moves it to one

or more evaporators or heat exchangers, which may be remote from the receiver. The low-

pressure refrigerant may be used as a single-phase heat-transfer fluid as in (A) of Fig. 5,

which eliminates the extra heat-exchange step and increased temperature difference encoun-

tered in a conventional system that uses a secondary refrigerant or brine. This approach may

simplify the design of process heat exchangers, where the large specific volumes of evapo-

rating refrigerant vapor would be troublesome. Alternatively, the pumped refrigerant in the

flooded system may be routed through conventional evaporators as in (B) and (C), or special

heat exchangers as in (D).

The flooded refrigeration system is helpful when special heat exchangers are necessary

for process reasons, or where multiple or remote exchangers are required.

3.2 Open-Cycle Operation

In many chemical processes, the product to be cooled can itself be used as the refrigerating

liquid. An example of this is in a natural gas gathering plant. Gas from the wells is cooled,

usually after compression and after some of the heavier components are removed as liquid.

This liquid may be expanded in a refrigeration cycle to further cool the compressed gas,

which causes more of the heavier components to condense. Excess liquid not used for re-

frigeration is drawn off as product. In the transportation of liquefied petroleum gas (LPG)

and of ammonia in ships and barges, the LPG or ammonia is compressed, cooled, and

expanded. The liquid portion after expansion is passed on as product until the ship is loaded.

Open-cycle operations are similar to closed-cycle operations, except that one or more

parts of the closed cycle may be omitted. For example, the compressor suction may be taken

directly from gas wells, rather than from an evaporator. A condenser may be used, and the

liquefied gas may be drained to storage tanks.

Compressors may be installed in series or parallel for operating flexibility or for partial

standby protection. With multiple reciprocating compressors, or with a centrifugal compres-

sor, gas streams may be picked up or discharged at several pressures if there is refrigerating

duty to be performed at intermediate temperatures. It always is more economical to refrig-

erate at the highest temperature possible.

Principal concerns in the open cycle involve dirt and contaminants, wet gas, compati-

bility of materials and lubrication circuits, and piping to and from the compressor. The

possibility of gas condensing under various ambient temperatures either during operation or