Page 471 - Mechanical Engineers' Handbook (Volume 4)

P. 471

460 Refrigeration

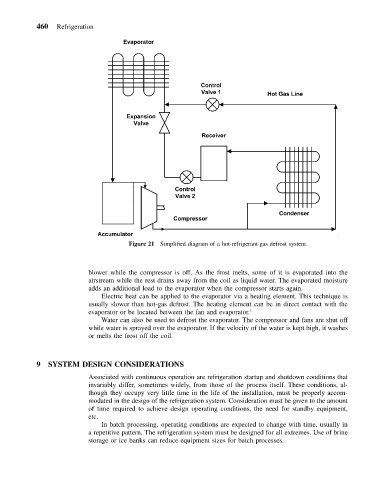

Figure 21 Simplified diagram of a hot-refrigerant-gas defrost system.

blower while the compressor is off. As the frost melts, some of it is evaporated into the

airstream while the rest drains away from the coil as liquid water. The evaporated moisture

adds an additional load to the evaporator when the compressor starts again.

Electric heat can be applied to the evaporator via a heating element. This technique is

usually slower than hot-gas defrost. The heating element can be in direct contact with the

evaporator or be located between the fan and evaporator. 1

Water can also be used to defrost the evaporator. The compressor and fans are shut off

while water is sprayed over the evaporator. If the velocity of the water is kept high, it washes

or melts the frost off the coil.

9 SYSTEM DESIGN CONSIDERATIONS

Associated with continuous operation are refrigeration startup and shutdown conditions that

invariably differ, sometimes widely, from those of the process itself. These conditions, al-

though they occupy very little time in the life of the installation, must be properly accom-

modated in the design of the refrigeration system. Consideration must be given to the amount

of time required to achieve design operating conditions, the need for standby equipment,

etc.

In batch processing, operating conditions are expected to change with time, usually in

a repetitive pattern. The refrigeration system must be designed for all extremes. Use of brine

storage or ice banks can reduce equipment sizes for batch processes.