Page 474 - Mechanical Engineers' Handbook (Volume 4)

P. 474

References 463

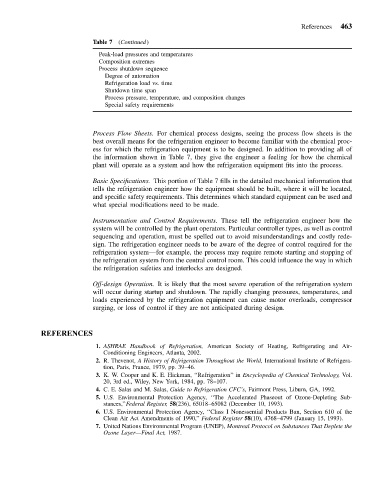

Table 7 (Continued)

Peak-load pressures and temperatures

Composition extremes

Process shutdown sequence

Degree of automation

Refrigeration load vs. time

Shutdown time span

Process pressure, temperature, and composition changes

Special safety requirements

Process Flow Sheets. For chemical process designs, seeing the process flow sheets is the

best overall means for the refrigeration engineer to become familiar with the chemical proc-

ess for which the refrigeration equipment is to be designed. In addition to providing all of

the information shown in Table 7, they give the engineer a feeling for how the chemical

plant will operate as a system and how the refrigeration equipment fits into the process.

Basic Specifications. This portion of Table 7 fills in the detailed mechanical information that

tells the refrigeration engineer how the equipment should be built, where it will be located,

and specific safety requirements. This determines which standard equipment can be used and

what special modifications need to be made.

Instrumentation and Control Requirements. These tell the refrigeration engineer how the

system will be controlled by the plant operators. Particular controller types, as well as control

sequencing and operation, must be spelled out to avoid misunderstandings and costly rede-

sign. The refrigeration engineer needs to be aware of the degree of control required for the

refrigeration system—for example, the process may require remote starting and stopping of

the refrigeration system from the central control room. This could influence the way in which

the refrigeration safeties and interlocks are designed.

Off-design Operation. It is likely that the most severe operation of the refrigeration system

will occur during startup and shutdown. The rapidly changing pressures, temperatures, and

loads experienced by the refrigeration equipment can cause motor overloads, compressor

surging, or loss of control if they are not anticipated during design.

REFERENCES

1. ASHRAE Handbook of Refrigeration, American Society of Heating, Refrigerating and Air-

Conditioning Engineers, Atlanta, 2002.

2. R. Thevenot, A History of Refrigeration Throughout the World, International Institute of Refrigera-

tion, Paris, France, 1979, pp. 39–46.

3. K. W. Cooper and K. E. Hickman, ‘‘Refrigeration’’ in Encyclopedia of Chemical Technology, Vol.

20, 3rd ed., Wiley, New York, 1984, pp. 78–107.

4. C. E. Salas and M. Salas, Guide to Refrigeration CFC’s, Fairmont Press, Liburn, GA, 1992.

5. U.S. Environmental Protection Agency, ‘‘The Accelerated Phaseout of Ozone-Depleting Sub-

stances,’’Federal Register, 58(236), 65018–65082 (December 10, 1993).

6. U.S. Environmental Protection Agency, ‘‘Class I Nonessential Products Ban, Section 610 of the

Clean Air Act Amendments of 1990,’’ Federal Register 58(10), 4768–4799 (January 15, 1993).

7. United Nations Environmental Program (UNEP), Montreal Protocol on Substances That Deplete the

Ozone Layer—Final Act, 1987.