Page 515 - Mechanical Engineers' Handbook (Volume 4)

P. 515

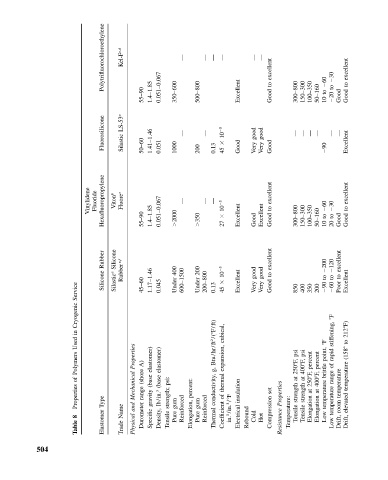

Polytrifluorochloroethylene Kel-F c,d — — — — — — excellent excellent

55–90 1.4–1.85 0.051–0.067 350–600 500–800 Excellent to Good 300–800 150–300 100–350 50–160 60 to 10 30 to 20 Good to Good

Fluorosilicone LS-53 a Silastic 50–60 1.41–1.46 0.051 1000 — 200 — 0.13 10 5 45 Good good Very good Very Good — — — — 90 — — Excellent

Vinylidene Fluoride Hexafluoropropylene Viton b Fluore c 55–90 1.4–1.85 0.051–0.067 2000 — 350 — — 10 5 27 Excellent Good Excellent excellent to Good 300–800 150–300 100–350 50–160 60 to 10 30 to 20 Good excellent to Good

Rubber Silicone excellent 200 120 excellent

Silicone Silastic a Rubber e,f 45–60 1.17–1.46 400 Under 600–1500 200 Under 200–800 10 5 Excellent good good to to to to Excellent

Service 0.045 0.13 45 Very Very Good 850 400 350 200 90 60 Poor

Cryogenic F

in cubical, stiffening, 212 F)

Used Btu/hr/ft 2 /( F/ft) psi psi F to (158

Polymers Properties A) elastomer) elastomer) g, expansion, 250 F, 400 F, percent percent point, brittle rapid of

of Mechanical (shore (base (base psi: thermal at at 250 F, 400 F, range temperature temperature

Properties Type and range gravity lb/in. 3 strength; gum percent: gum conductivity, of insulation set Properties strength strength at at temperature temperature room elevated

8 Name Durometer Specific Density, Tensile Pure Reinforced Elongation, Pure Reinforced Thermal Coefficient in. 3 /in. 3 / F Electrical Rebound Cold Hot Compression Resistance Temperature: Tensile Tensile Elongation Elongation Low

Table Elastomer Trade Physical Low Drift, Drift,

504