Page 17 - Mechanics Analysis Composite Materials

P. 17

2 Mechanics and analysis of composite materials

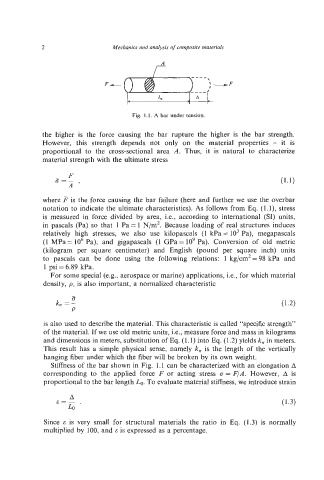

Fig. 1.1. A bar under tension.

the higher is the force causing the bar rupture the higher is the bar strength.

However, this strength depends not only on the material properties - it is

proportional to the cross-sectional area A. Thus, it is natural to characterize

material strength with the ultimate stress

a=- F

A’

where F is the force causing the bar failure (here and further we use the overbar

notation to indicate the ultimate characteristics). As follows from Eq. (1. l), stress

is measured in force divided by area, i.e., according to international (SI) units,

in pascals (Pa) so that 1 Pa = 1 N/m2. Because loading of real structures induces

relatively high stresses, we also use kilopascals (1 kPa = IO3 Pa), megapascals

(1 MPa= lo6 Pa), and gigapascals (1 GPa = 10’ Pa). Conversion of old metric

(kilogram per square centimeter) and English (pound per square inch) units

to pascals can be done using the following relations: 1 kg/cm2=98 kPa and

1 psi =6.89 kPa.

For some special (e.g., aerospace or marine) applications, Le., for which material

density, p, is also important, a normalized characteristic

a

k, = -

P

is also used to describe the material. This characteristic is called “specific strength”

of the material. If we use old metric units, Le., measure force and mass in kilograms

and dimensions in meters, substitution of Eq. (1.1) into Eq. (1.2) yields k, in meters.

This result has a simple physical sense, namely k, is the length of the vertically

hanging fiber under which the fiber will be broken by its own weight.

Stiffnessof the bar shown in Fig. 1.1 can be characterized with an elongation A

corresponding to the applied force F or acting stress u = F/A. However, A is

proportional to the bar length LO.To evaluate material stiffness, we introduce strain

A

E=-.

LO

Since E is very small for structural materials the ratio in Eq. (1.3) is normally

multiplied by 100, and E is expressed as a percentage.