Page 224 - Mechanics Analysis Composite Materials

P. 224

Chapter 4. Mechanics of a composite layer 209

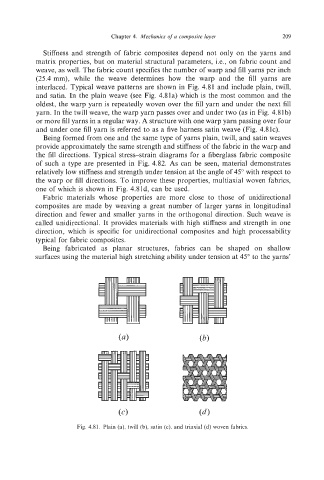

Stiffness and strength of fabric composites depend not only on the yarns and

matrix properties, but on material structural parameters, i.e., on fabric count and

weave, as well. The fabric count specifies the number of warp and fill yarns per inch

(25.4 mm), while the weave determines how the warp and the fill yarns are

interlaced. Typical weave patterns are shown in Fig. 4.81 and include plain, twill,

and satin. In the plain weave (see Fig. 4.81a) which is the most common and the

oldest, the warp yarn is repeatedly woven over the fill yarn and under the next fill

yarn. In the twill weave, the warp yarn passes over and under two (as in Fig. 4.8 1b)

or more fill yarns in a regular way. A structure with one warp yarn passing over four

and under one fill yarn is referred to as a five harness satin weave (Fig. 4.81~).

Being formed from one and the same type of yarns plain, twill, and satin weaves

provide approximately the same strength and stiffness of the fabric in the warp and

the fill directions. Typical stress-strain diagrams for a fiberglass fabric composite

of such a type are presented in Fig. 4.82. As can be seen, material demonstrates

relatively low stiffness and strength under tension at the angle of 45" with respect to

the warp or fill directions. To improve these properties, multiaxial woven fabrics,

one of which is shown in Fig. 4.81d, can be used.

Fabric materials whose properties are more close to those of unidirectional

composites are made by weaving a great number of larger yarns in longitudinal

direction and fewer and smaller yarns in the orthogonal direction. Such weave is

called unidirectional. It provides materials with high stiffness and strength in one

direction, which is specific for unidirectional composites and high processability

typical for fabric composites.

Being fabricated as planar structures, fabrics can be shaped on shallow

surfaces using the material high stretching ability under tension at 45" to the yarns'

(c) (4

Fig. 4.81. Plain (a), twill (b), satin (c),and triaxial (d) woven fabrics.