Page 107 - Mechanics of Asphalt Microstructure and Micromechanics

P. 107

100 Ch a p t e r F o u r

non-invasive. For most invasive techniques, measurements tend to be limited to only a

few points to minimize interference and cost. To obtain accurate displacement mea-

surements, testers using invasive techniques must make sure that the sensors deform

compatibly with the material being measured so that the interference of the sensors

with the material being tested is minimized. For non-invasive measurements, there are

no such limitations and thus techniques such as imaging offer the potential for non-

invasive strain measurement of bonded granular materials such as AC and cement

concrete. Non-invasive measurements have been widely applied in medical science

(IAEA, 1995), in fluid flow measurement (Hanssan et al., 1991), and in granular particle

tracking (Warr, 1994). These methods are presented first for the two-dimensional (2D)

case using optical imaging and are then extended to the three-dimensional (3D) case

using XCT imaging. A digital image correlation method, mainly applicable to the 2D

case, will be discussed in the last section of this chapter.

4.2 2D Methodology

This section presents a method that permits non-invasive evaluation of the strains in

the mastic using optical imaging of particle positions. It will be directly illustrated for

specimens tested in the GLWT, while the methodology is equally applicable for use

with other testing systems and specimens.

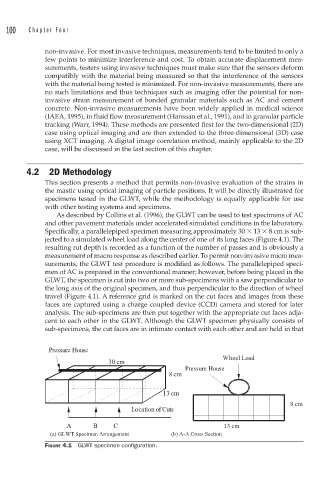

As described by Collins et al. (1996), the GLWT can be used to test specimens of AC

and other pavement materials under accelerated simulated conditions in the laboratory.

Specifically, a parallelepiped specimen measuring approximately 30 13 8 cm is sub-

jected to a simulated wheel load along the center of one of its long faces (Figure 4.1). The

resulting rut depth is recorded as a function of the number of passes and is obviously a

measurement of macro response as described earlier. To permit non-invasive micro mea-

surements, the GLWT test procedure is modified as follows. The parallelepiped speci-

men of AC is prepared in the conventional manner; however, before being placed in the

GLWT, the specimen is cut into two or more sub-specimens with a saw perpendicular to

the long axis of the original specimen, and thus perpendicular to the direction of wheel

travel (Figure 4.1). A reference grid is marked on the cut faces and images from these

faces are captured using a charge coupled device (CCD) camera and stored for later

analysis. The sub-specimens are then put together with the appropriate cut faces adja-

cent to each other in the GLWT. Although the GLWT specimen physically consists of

sub-specimens, the cut faces are in intimate contact with each other and are held in that

Pressure House

Wheel Load

30 cm

Pressure House

8 cm

13 cm

8 cm

Location of Cuts

A B C 13 cm

(a) GLWT Specimen Arrangement (b) A-A Cross Section

FIGURE 4.1 GLWT specimen confi guration.