Page 369 - Mechanics of Asphalt Microstructure and Micromechanics

P. 369

Digital Specimen and Digital T est-Integration of Microstructure into Simulation 361

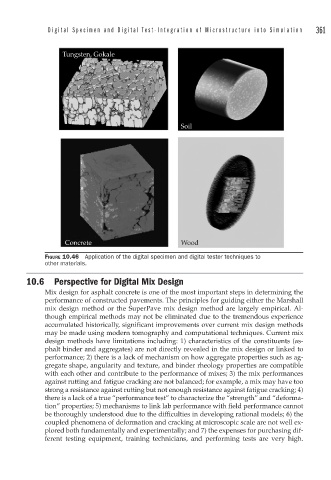

Tungsten, Gokale

Soil

Concrete Wood

FIGURE 10.46 Application of the digital specimen and digital tester techniques to

other materials.

10.6 Perspective for Digital Mix Design

Mix design for asphalt concrete is one of the most important steps in determining the

performance of constructed pavements. The principles for guiding either the Marshall

mix design method or the SuperPave mix design method are largely empirical. Al-

though empirical methods may not be eliminated due to the tremendous experience

accumulated historically, significant improvements over current mix design methods

may be made using modern tomography and computational techniques. Current mix

design methods have limitations including: 1) characteristics of the constituents (as-

phalt binder and aggregates) are not directly revealed in the mix design or linked to

performance; 2) there is a lack of mechanism on how aggregate properties such as ag-

gregate shape, angularity and texture, and binder rheology properties are compatible

with each other and contribute to the performance of mixes; 3) the mix performances

against rutting and fatigue cracking are not balanced; for example, a mix may have too

strong a resistance against rutting but not enough resistance against fatigue cracking; 4)

there is a lack of a true “performance test” to characterize the “strength” and “deforma-

tion” properties; 5) mechanisms to link lab performance with field performance cannot

be thoroughly understood due to the difficulties in developing rational models; 6) the

coupled phenomena of deformation and cracking at microscopic scale are not well ex-

plored both fundamentally and experimentally; and 7) the expenses for purchasing dif-

ferent testing equipment, training technicians, and performing tests are very high.