Page 224 - Mechatronics for Safety, Security and Dependability in a New Era

P. 224

Ch43-I044963.fm Page 208 Tuesday, August 1, 2006 3:58 PM

Ch43-I044963.fm

208

208 Page 208 Tuesday, August 1, 2006 3:58 PM

manufacturing processes occur in the manufacturing systems. A reactive scheduling method for delays

of manufacturing processes was proposed in the previous research papers (Tanimizu 2002). This

method used Genetic Algorithm (GA) to generate new feasible production schedules. The previous

paper showed that the initial production schedule is modified and improved through the GA based

reactive scheduling processes.

The objective of the research is to propose a new GA based reactive scheduling method for tardiness

minimization scheduling problems, aiming at improving the disturbed production schedule efficiently

and generating suitable production schedules faster than the previous reactive scheduling method. A

prototype of reactive scheduling system is developed and applied to computational experiments.

CURRENT REACTIVE SCHEDULING METHOD

Reactive scheduling process is activated, only when the initial production schedule cannot satisfy the

constraint on the make-span, due to the unscheduled disruptions. It is necessary to consider the

progress of the manufacturing process in the reactive scheduling process.

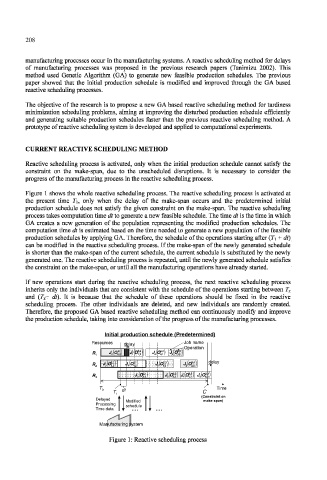

Figure 1 shows the whole reactive scheduling process. The reactive scheduling process is activated at

the present time T\, only when the delay of the make-span occurs and the predetermined initial

production schedule does not satisfy the given constraint on the make-span. The reactive scheduling

process takes computation time dt to generate a new feasible schedule. The time dt is the time in which

GA creates a new generation of the population representing the modified production schedules. The

computation time dt is estimated based on the time needed to generate a new population of the feasible

production schedules by applying GA. Therefore, the schedule of the operations starting after (T\ + dt)

can be modified in the reactive scheduling process. If the make-span of the newly generated schedule

is shorter than the make-span of the current schedule, the current schedule is substituted by the newly

generated one. The reactive scheduling process is repeated, until the newly generated schedule satisfies

the constraint on the make-span, or until all the manufacturing operations have already started.

Tf new operations start during the reactive scheduling process, the next reactive scheduling process

inherits only the individuals that are consistent with the schedule of the operations starting between T x

and (T x+ dt). It is because that the schedule of these operations should be fixed in the reactive

scheduling process. The other individuals are deleted, and new individuals are randomly created.

Therefore, the proposed GA based reactive scheduling method can continuously modify and improve

the production schedule, taking into consideration of the progress of the manufacturing processes.

Initial production schedule (Predetermined)

Initial production schedule (Predetermined)

Resources delay Job name

( ) 1 , 1 ( ) 3 , 2 ( ) Operation

2 , 1

4 , 3

O

J O ( ) J O

R 1 2 O 1 , 2 1 J 1 , 1 4 J 1 , 4 3 1 , 3

( )

( )

( )

( )

J 3 O 1 , 1 J 4 O 2 , 1 J 1 O 3 , 2 J 2 O 4 , 3 delay

R 2 2 , 3 2 , 4 2 , 1 2 , 2

( ) ( ) ( ) ( )

J 1 , 2 J 2 , 2 J 3 , 3 J 4 , 3

R 3 3 O 3 , 3 2 O 3 , 2 1 O 3 , 1 4 O 3 , 4

Time

dt

T 0 Time

T 1 C

(Constraint on

Delayed Modified t make-span)

Delayed

Modified

Processing schedule I

Processing

schedule

Time datan ... I i ...

Time data

Manufacturing system

Manufacturing system

Figure 1: Reactive scheduling process