Page 219 - Mechatronics for Safety, Security and Dependability in a New Era

P. 219

Ch42-I044963.fm Page 203 Tuesday, August 1, 2006 3:57 PM

1, 2006

3:57 PM

Page 203

Tuesday, August

Ch42-I044963.fm

203

203

S c h e d u l i n g H o l o n

l a n d

T

i

/ 1

J b H 0 n 1 J b H n 2 J b H n n

P , .°, ,, p?,'. . n g » y P , .°, ,, p?,'n°. ., t » p, .°, ,, p?,'.°. ., t»

p_^j—o__

T

•

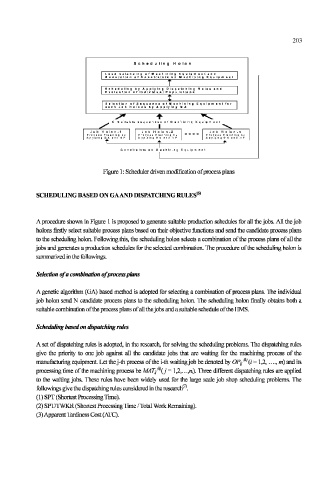

Figure 1: Scheduler driven modification of process plans

SCHEDULING BASED ON GAAND DISPATCHING RULES (6)

A procedure shown in Figure 1 is proposed to generate suitable production schedules for all the jobs. All the job

holons firstly select suitable process plans based on their objective functions and send the candidate process plans

to the scheduling holon. Following this, the scheduling holon selects a combination of the process plans of all the

jobs and generates a production schedules for the selected combination. The procedure of the scheduling holon is

summarized in the followings.

Selection of a combination of process plans

A genetic algorithm (GA) based method is adopted for selecting a combination of process plans. The individual

job holon send N candidate process plans to the scheduling holon. The scheduling holon finally obtains both a

suitable combination of the process plans of all the jobs and a suitable schedule of the HMS.

Scheduling based on dispatching rules

A set of dispatching rules is adopted, in the research, for solving the scheduling problems. The dispatching rules

give the priority to one job against all the candidate jobs that are waiting for the machining process of the

(k>

manufacturing equipment. Let the j-th process of the i-th waiting job be denoted by OPy (i = 1,2,...., rri) and its

processing time of the machining process be MAT^(j = 1,2,...,«;). Three different dispatching rules are applied

to the waiting jobs. These rules have been widely used for the large scale job shop scheduling problems. The

7 1

followings give the dispatching rules considered in the research' - .

(1) SPT (Shortest Processing Time).

(2) SPTTWKR (Shortest Processing Time / Total Work Remaining).

(3) Apparent Tardiness Cost (ATC).