Page 305 - Mechatronics for Safety, Security and Dependability in a New Era

P. 305

Ch58-I044963.fm Page 289 Tuesday, August 1, 2006 4:39 PM

1, 2006

Tuesday, August

4:39 PM

Ch58-I044963.fm

Page 289

289

289

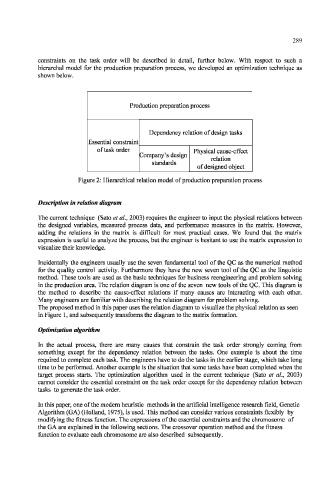

constraints on the task order will be described in detail, further below. With respect to such a

hierarchal model for the production preparation process, we developed an optimization technique as

shown below.

Production preparation process

Dependency relation of design tasks

Essential constraint

of task order Physical cause-effect

Company's design

relation

standards

of designed object

Figure 2: Hierarchical relation model of production preparation process

Description in relation diagram

The current technique (Sato et ah, 2003) requires the engineer to input the physical relations between

the designed variables, measured process data, and performance measures in the matrix. However,

adding the relations in the matrix is difficult for most practical cases. We found that the matrix

expression is useful to analyze the process, but the engineer is hesitant to use the matrix expression to

visualize their knowledge.

Incidentally the engineers usually use the seven fundamental tool of the QC as the numerical method

for the quality control activity. Furthermore they have the new seven tool of the QC as the linguistic

method. These tools are used as the basic techniques for business reengineering and problem solving

in the production area. The relation diagram is one of the seven new tools of the QC. This diagram is

the method to describe the cause-effect relations if many causes are interacting with each other.

Many engineers are familiar with describing the relation diagram for problem solving.

The proposed method in this paper uses the relation diagram to visualize the physical relation as seen

in Figure 1, and subsequently transforms the diagram to the matrix formation.

Optimization algorithm

In the actual process, there are many causes that constrain the task order strongly coming from

something except for the dependency relation between the tasks. One example is about the time

required to complete each task. The engineers have to do the tasks in the earlier stage, which take long

time to be performed. Another example is the situation that some tasks have been completed when the

target process starts. The optimization algorithm used in the current technique (Sato et al., 2003)

cannot consider the essential constraint on the task order except for the dependency relation between

tasks to generate the task order.

In this paper, one of the modern heuristic methods in the artificial intelligence research field, Genetic

Algorithm (GA) (Holland, 1975), is used. This method can consider various constraints flexibly by

modifying the fitness function. The expressions of the essential constraints and the chromosome of

the GA are explained in the following sections. The crossover operation method and the fitness

function to evaluate each chromosome are also described subsequently.