Page 311 - Mechatronics for Safety, Security and Dependability in a New Era

P. 311

Ch59-I044963.fm Page 295 Thursday, July 27, 2006 8:59 AM

Page 295

8:59 AM

Ch59-I044963.fm

Thursday, July 27, 2006

295

295

• A case study about construction process of "Curtain Wall" ;

modeling by process intermediate

engineering tool 3D-CG simulator final deliverables

design ttOM modeling ^ decision <-f assembly

m;Ucn;]l library creation —

manufacturing BOM modelin

(1)

product design

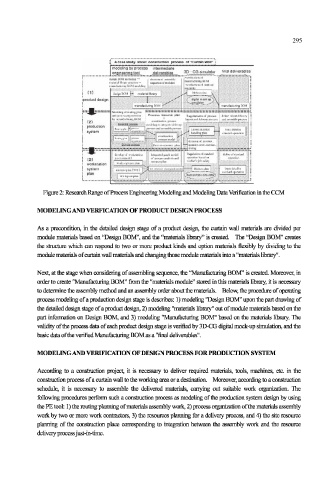

Figure 2: Research Range of Process Engineering Modeling and Modeling Data Verification in the CCM

MODELING AND VERFICATION OF PRODUCT DESIGN PROCESS

As a precondition, in the detailed design stage of a product design, the curtain wall materials are divided per

module materials based on "Design BOM", and the "materials library" is created. The "Design BOM" creates

the structure which can respond to two or more product kinds and option materials flexibly by dividing to the

module materials of curtain wall materials and changing those module materials into a "materials library".

Next, at the stage when considering of assembling sequence, the "Manufacturing BOM" is created. Moreover, in

order to create "Manufacturing BOM" from the "materials module" stored in this materials library, it is necessary

to determine the assembly method and an assembly order about the materials. Below, the procedure of operating

process modeling of a production design stage is describes: 1) modeling "Design BOM" upon the part drawing of

the detailed design stage of a product design, 2) modeling "materials library" out of module materials based on the

part information on Design BOM, and 3) modeling "Manufacturing BOM" based on the materials library. The

validity of the process data of each product design stage is verified by 3D-CG digital mock-up simulation, and the

basic data of the verified Manufacturing BOM as a "final deliverables".

MODELING AND VERIFICATION OF DESIGN PROCESS FOR PRODUCTION SYSTEM

According to a construction project, it is necessary to deliver required materials, tools, machines, etc. in the

construction process of a curtain wall to the working area or a destination. Moreover, according to a construction

schedule, it is necessary to assemble the delivered materials, carrying out suitable work organization. The

following procedures perform such a construction process as modeling of the production system design by using

the PE tool: 1) the routing planning of materials assembly work, 2) process organization of the materials assembly

work by two or more work contractors, 3) the resources planning for a delivery process, and 4) the site resource

planning of the construction place corresponding to integration between the assembly work and the resource

delivery process just-in-time.