Page 398 - Mechatronics for Safety, Security and Dependability in a New Era

P. 398

Ch77-I044963.fm Page 382 Tuesday, August 1, 2006 9:45 PM

Ch77-I044963.fm

382

382 Page 382 Tuesday, August 1, 2006 9:45 PM

Jagged shape

Magnified

1000|im

Solid needle

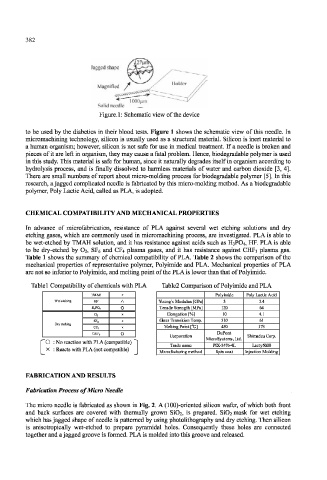

Figure. 1: Schematic view of the device

to be used by the diabetics in their blood tests. Figure 1 shows the schematic view of this needle. In

micromachining technology, silicon is usually used as a structural material. Silicon is inert material to

a human organism; however, silicon is not safe for use in medical treatment. If a needle is broken and

pieces of it are left in organism, they may cause a fatal problem. Hence, biodegradable polymer is used

in this study. This material is safe for human, since it naturally degrades itself in organism according to

hydrolysis process, and is finally dissolved to harmless materials of water and carbon dioxide [3, 4].

There are small numbers of report about micro-molding process for biodegradable polymer [5]. In this

research, a jagged complicated needle is fabricated by this micro-molding method. As a biodegradable

polymer, Poly Lactic Acid, called as PLA, is adopted.

CHEMICAL COMPATIBILITY AND MECHANICAL PROPERTIES

In advance of microfabrication, resistance of PLA against several wet etching solutions and dry

etching gases, which are commonly used in micromachining process, are investigated. PLA is able to

be wet-etched by TMAH solution, and it has resistance against acids such as H3PO4, HF. PLA is able

to be dry-etched by O2, SFe and CF4 plasma gases, and it has resistance against CHF3 plasma gas.

Table 1 shows the summary of chemical compatibility of PLA. Table 2 shows the comparison of the

mechanical properties of representative polymer, Polyimide and PLA. Mechanical properties of PLA

are not so inferior to Polyimide, and melting point of the PLA is lower than that of Polyimide.

Tablel Compatibility of chemicals with PLA Table2 Comparison of Polyimide and PLA

TMAH x Polyimide Poly Lactic Acid

Wet etching I IF Young's Modulus [GPa] 3 3.4

BjPO, 0 Tensile Strength |MPa| 120 64

O, x Elongation [%] 10 4.1

si ,. 7 X Glass Transition Temp. 310 61

Diy etching

CT, Melting Point [°C] 450 173

o Corporation Shimadzu Corp.

CHK 3 DuPont

MicroSystcms, Ltd.

O : No reaction with PLA (compatible) ~~|

Trade name PIX-3476-4L Lacty500O

X : Reacts with PLA (not compatible) Manufacturing method Spin coat Injection Molding

FABRICATION AND RESULTS

Fabrication Process of Micro Needle

The micro needle is fabricated as shown in Fig. 2. A (lOO)-oriented silicon wafer, of which both front

and back surfaces are covered with thermally grown SiC>2, is prepared. SiC>2 mask for wet etching

which has jagged shape of needle is patterned by using photolithography and dry etching. Then silicon

is anisotropically wet-etched to prepare pyramidal holes. Consequently these holes are connected

together and a jagged groove is formed. PLA is molded into this groove and released.