Page 394 - Mechatronics for Safety, Security and Dependability in a New Era

P. 394

Ch76-I044963.fm Page 378 Tuesday, August 1, 2006 8:30 PM

Ch76-I044963.fm

378

378 Page 378 Tuesday, August 1, 2006 8:30 PM

So far, the behavior of gland packing has been considered theoretically, and the measurement of its

[1] [3]

radial pressure has been performed using pressure measuring film, strain gages, etc. ~ . However,

these methods have had problems involving their inability to measure the pressure changes over time

and the distribution of radial pressure.

(Inside)

(Outside)

BEBri Axial Compression (Inside) (Outside)

Micro Washer

Gland

Gland Stem Radial Micro Washer

Pressure Pressure Sensor

Packing — Pressure Sensor

Packing

Gland

Gland

Packing

Packing

Grease

Grease

Radial Pressure

Radial Pressure

Fig.2 Method of measuring radial pressure of gland

Fig.l Composition of a control valve packing through grease

0 900 1809 2500 39D0 -4

limeb)

Fig.3 Comparison of measured value Fig.4 Structure of Measuring Device Fig.5 Photo of Measuring Device

METHOD OF MEASURING RADIAL PRESSURE THROUGH GREASE AND EVALUATION

OF THIS METHOD

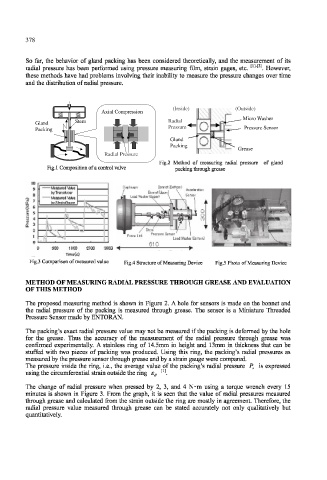

The proposed measuring method is shown in Figure 2. A hole for sensors is made on the bonnet and

the radial pressure of the packing is measured through grease. The sensor is a Miniature Threaded

Pressure Sensor made by ENTORAN.

The packing's exact radial pressure value may not be measured if the packing is deformed by the hole

for the grease. Thus the accuracy of the measurement of the radial pressure through grease was

confirmed experimentally. A stainless ring of 14.5mm in height and 13mm in thickness that can be

stuffed with two pieces of packing was produced. Using this ring, the packing's radial pressures as

measured by the pressure sensor through grease and by a strain gauge were compared.

The pressure inside the ring, i.e., the average value of the packing's radial pressure P r is expressed

using the circumferential strain outside the ring e e [i]

The change of radial pressure when pressed by 2, 3, and 4 N-m using a torque wrench every 15

minutes is shown in Figure 3. From the graph, it is seen that the value of radial pressures measured

through grease and calculated from the strain outside the ring are mostly in agreement. Therefore, the

radial pressure value measured through grease can be stated accurately not only qualitatively but

quantitatively.