Page 392 - Mechatronics for Safety, Security and Dependability in a New Era

P. 392

Ch75-I044963.fm Page 376 Tuesday, August 1, 2006 5:58 PM

Ch75-I044963.fm

376

376 Page 376 Tuesday, August 1, 2006 5:58 PM

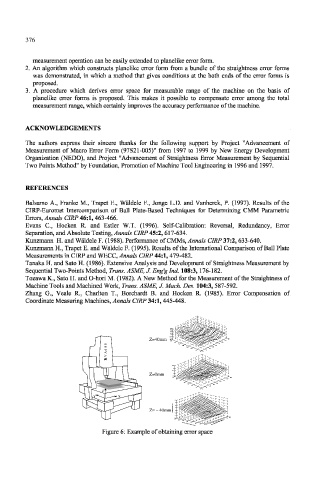

measurement operation can be easily extended to planelike error form.

An algorithm which constructs planelike error form from a bundle of the straightness error forms

was demonstrated, in which a method that gives conditions at the both ends of the error forms is

proposed.

A procedure which derives error space for measurable range of the machine on the basis of

planelike error forms is proposed. This makes it possible to compensate error among the total

measurement range, which certainly improves the accuracy performance of the machine.

ACKNOWLEDGEMENTS

The authors express their sincere thanks for the following support by Project "Advancement of

Measurement of Macro Error Form (97S21-005)" from 1997 to 1999 by New Energy Development

Organization (NEDO), and Project "Advancement of Straightness Error Measurement by Sequential

Two Points Method" by Foundation, Promotion of Machine Tool Engineering in 1996 and 1997.

REFERENCES

Balsamo A., Franke M., Trapet E., Waldele F., Jonge L.D. and Vanherck, P. (1997). Results of the

CIRP-Euromet Intercomparison of Ball Plate-Based Techniques for Determining CMM Parametric

Errors, Annals CIRP 46:1, 463-466.

Evans C, Hocken R. and Estler W.T. (1996). Self-Calibration: Reversal, Redundancy, Error

Separation, and Absolute Testing, Annals CIRP 45:2, 617-634.

Kunzmann H. and Waldele F. (1988). Performance of CMMs, Annals CIRP 37:2, 633-640.

Kunzmann H., Trapet E. and Waldele F. (1995). Results of the International Comparison of Ball Plate

Measurements in CIRP and WECC, Annals CIRP 44:1, 479-482.

Tanaka H. and Sato H. (1986). Extensive Analysis and Development of Straightness Measurement by

Sequential Two-Points Method, Trans. ASME, J. Eng'glnd. 108:3, 176-182.

Tozawa K., Sato H. and O-hori M. (1982). A New Method for the Measurement of the Straightness of

Machine Tools and Machined Work, Trans. ASME, J. Mack Des. 104:3, 587-592.

Zhang G., Veale R., Charlton T., Borchardt B. and Hocken R. (1985). Error Compensation of

Coordinate Measuring Machines, Annals CIRP 34:1, 445-448.

0.8

0.6

0.4 0.2 0

s Z=40mm - -0.2 -0.4 350 0 . 4 -0.6 300 250 200 200 250 300 350 400

Z=40mm

R V A 6 0 0 150 100 50 0 0 50 100 150

R

R V A 6 0 0 009VAH

0.5 0

I Z=0mm -0.5 -1.5 -1 350 400

J

Z=0mm

300

250 300 350

200 250

200

150

150

100 100

50 50

0 0

Z Z

Y Y X X

5

4

( r o µ ) 3

m

2 r r e s s

Z= – 40mm e n g t h 1

Z= -

40mm j

0 a r t S

-1

400

-2 350

350 300

300 250

250 200

200 150 X - axis (mm)

150

100

100 50 50 Feed along

( 0 0

Feed a long Y - axis mm)

Figure 6: Example of obtaining error space