Page 389 - Mechatronics for Safety, Security and Dependability in a New Era

P. 389

Ch75-I044963.fm Page 373 Tuesday, August 1, 2006 5:58 PM

Page 373

1, 2006

Tuesday, August

5:58 PM

Ch75-I044963.fm

373

373

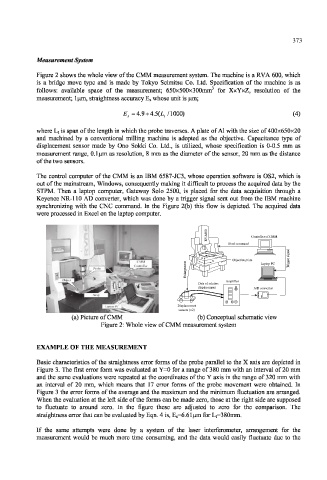

Measurement System

Figure 2 shows the whole view of the CMM measurement system. The machine is a RVA 600, which

is a bridge move type and is made by Tokyo Seimitsu Co. Ltd. Specification of the machine is as

follows: available space of the measurement; 650x500x300mm for XxYxZ, resolution of the

measurement; 1 urn, straightness accuracy E s whose unit is urn;

E s = 4.9 + 4.5(i, /1000) (4)

where L t is span of the length in which the probe traverses. A plate of Al with the size of 400x650x20

and machined by a conventional milling machine is adopted as the objective. Capacitance type of

displacement sensor made by Ono Sokki Co. Ltd., is utilized, whose specification is 0-0.5 mm as

measurement range, 0.1 um as resolution, 8 mm as the diameter of the sensor, 20 mm as the distance

of the two sensors.

The control computer of the CMM is an IBM 6587-JC3, whose operation software is OS2, which is

out of the mainstream, Windows, consequently making it difficult to process the acquired data by the

STPM. Then a laptop computer, Gateway Solo 2500, is placed for the data acquisition through a

Keyence NR-110 AD converter, which was done by a trigger signal sent out from the IBM machine

synchronizing with the CNC command. In the Figure 2(b) this flow is depicted. The acquired data

were processed in Excel on the laptop computer.

0

0

6

A Controller of CMM

Controller ofCMM

V

R

Feed command

l

a

n

g

i

s

Z r

Y Objective plate e

t X g

n g

e Laptop PC i

m r T

e

g

r

a

l

n

E

Amplifier

Data of relative

displacement A/D converter

Displacement

sensors (×2)

(a) Picture of CMM (b) Conceptual schematic view

Figure 2: Whole view of CMM measurement system

EXAMPLE OF THE MEASUREMENT

Basic characteristics of the straightness error forms of the probe parallel to the X axis are depicted in

Figure 3. The first error form was evaluated at Y=0 for a range of 380 mm with an interval of 20 mm

and the same evaluations were repeated at the coordinates of the Y axis in the range of 320 mm with

an interval of 20 mm, which means that 17 error forms of the probe movement were obtained. In

Figure 3 the error forms of the average and the maximum and the minimum fluctuation are arranged.

When the evaluation at the left side of the forms can be made zero, those at the right side are supposed

to fluctuate to around zero. In the figure these are adjusted to zero for the comparison. The

straightness error that can be evaluated by Eqn. 4 is, E s=6.61um for Li=380mm.

If the same attempts were done by a system of the laser interferometer, arrangement for the

measurement would be much more time consuming, and the data would easily fluctuate due to the