Page 385 - Mechatronics for Safety, Security and Dependability in a New Era

P. 385

Ch74-I044963.fm Page 369 Tuesday, August 1, 2006 9:45 PM

Page 369

Tuesday, August

1, 2006

9:45 PM

Ch74-I044963.fm

369

369

end coordinates of switch motions, which are estimated based on the CL&NC information previously

acquired. Moreover, it has the function to store the machine coordinates in the measuring point based

on CL data to the specific file promptly.

EXPERIMENT

We executed experiment to verify the feasibility of On-machine work piece measurement with laser

displacement sensor on 5-axis machining center in our research. Its major objectives were to:

^-Confirm that the measurement system perform the intended task smoothly.

^Verify that the laser displacement sensor can measure glossy surface of die, which is finish-

machined by ball end mill.

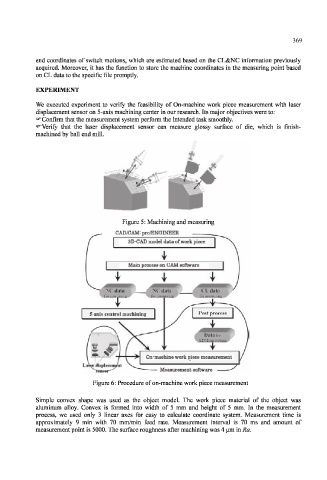

Figure 5: Machining and measuring

CAD/CAM: pro/ENGINEEK

3D-CAD model data of work piece

Main process on CAM software

On-machine work piece measurement

Measurement software -^

Figure 6: Procedure of on-machine work piece measurement

Simple convex shape was used as the object model. The work piece material of the object was

aluminum alloy. Convex is formed into width of 5 mm and height of 5 mm. In the measurement

process, we used only 3 linear axes for easy to calculate coordinate system. Measurement time is

approximately 9 min with 70 mm/min feed rate. Measurement interval is 70 ms and amount of

measurement point is 5000. The surface roughness after machining was 4 urn in Ra.