Page 383 - Mechatronics for Safety, Security and Dependability in a New Era

P. 383

Ch74-I044963.fm Page 367 Tuesday, August 1, 2006 9:45 PM

Tuesday, August 1, 2006

Page 367

9:45 PM

Ch74-I044963.fm

367

367

the surface as correctly as possible for executing surface measurement with high accuracy. Then, as

mentioned above, we tiy to use additional two rotary axes of 5-axis machining center for surface

measurement. Laser vector is traced by using orientation control of the spindle on five axis machining

center as shown in Figure l(b). With this method, not only measurement error is reduced but also all

surface measurement in particular die of convex is enabled. For these reason, On-machine work piece

measurement on 5-axis controlled machining center has an advantage for work piece measurement

after machining.

Circuit of signal amplification

Semiconductor laser

Receive light element

Object lens

Receive light lens

Work piece J

Displacement 1 ^ ^ f ^ ^ Standard position

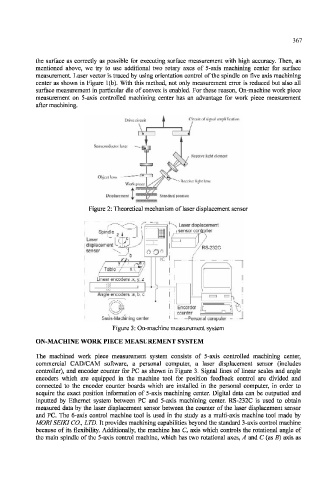

Figure 2: Theoretical mechanism of laser displacement sensor

I Spindle

: Laser

L

| displacement

: sensor

I

i J

L- — 5axis-Machining center — — L_ —Personal computer

Figure 3: On-machine measurement system

ON-MACHINE WORK PIECE MEASUREMENT SYSTEM

The machined work piece measurement system consists of 5-axis controlled machining center,

commercial CAD/CAM software, a personal computer, a laser displacement sensor (includes

controller), and encoder counter for PC as shown in Figure 3. Signal lines of linear scales and angle

encoders which are equipped in the machine tool for position feedback control are divided and

connected to the encoder counter boards which are installed in the personal computer, in order to

acquire the exact position information of 5-axis machining center. Digital data can be outputted and

inputted by Ethernet system between PC and 5-axis machining center. RS-232C is used to obtain

measured data by the laser displacement sensor between the counter of the laser displacement sensor

and PC. The 6-axis control machine tool is used in the study as a multi-axis machine tool made by

MORISEIKI CO., LTD. It provides machining capabilities beyond the standard 3-axis control machine

because of its flexibility. Additionally, the machine has C s axis which controls the rotational angle of

the main spindle of the 5-axis control machine, which has two rotational axes, A and C (as B) axis as