Page 113 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 113

92 Membranes for Industrial Wastewater Recovery and Re-use

Figure 3.7 4 Electron micrograph of biofilm structure. The length of the white bar represents 10 km

.,

% 1000

O 100

L

g$ 10

go 1

0,

-8

E 0.1

4

Jun-01 Jul-01 Sep-01 Nov-01 Dec-01 Feb-02

Sample Date

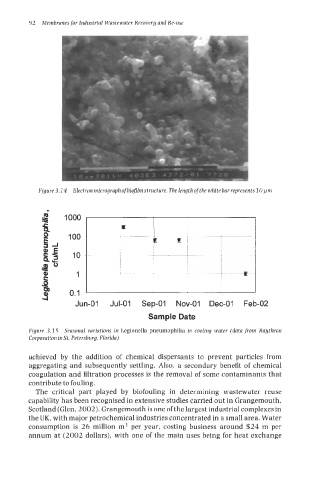

Figure 3.1 5 Seasonal variations in Legionella pneumophilia in cooling water (data from Raytheon

Corporation in St. Petersburg, Florida)

achieved by the addition of chemical dispersants to prevent particles from

aggregating and subsequently settling. Also, a secondary benefit of chemical

coagulation and filtration processes is the removal of some contaminants that

contribute to fouling.

The critical part played by biofouling in determining wastewater reuse

capability has been recognised in extensive studies carried out in Grangemouth,

Scotland (Glen, 2002). Grangemouth is one of the largest industrial complexes in

the UK, with major petrochemical industries concentrated in a small area. Water

consumption is 26 million m3 per year, costing business around $24 m per

annum at (2002 dollars), with one of the main uses being for heat exchange