Page 174 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 174

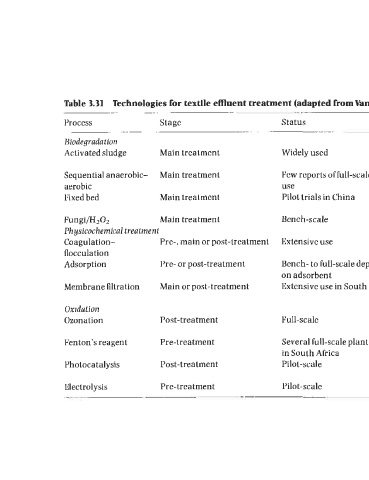

Table 3.31 Technologies for textile effluent treatment (adapted from Wndevivere et al., 1998)

-

Process Stage Status Performance Limitations

Biodegradation

Activated sludge Main treatment Widely used Bulk COD removal: partial High residual COD. ammonia,

nitrification colour

Sequential anaerobic- Main treatment Few reports of full-scale Better COD and colour High residual COD, colour

aerobic use removal than AS alone

Fixed bed Main treatment Pilot trials in China Better COD and colour Some residual colour

removal than AS

Fungi/H202 Main treatment Bench-scale Full decolourisation

Physicochemical treatment

Coagulation- Pre-, main or post-treatment Extensive use Almost full decolourisation; Unreliable performance: sludge

flocculation water reuse disposal

Adsorption Pre- or post-treatment Bench- to full-scale depending Water reuse with newer Sludge disposal or adsorbent

on adsorbent adsorbents regeneration

Membrane filtration Main or post-treatment Extensive use in South Africa Reliable performance; water Concentrate management

reuse

Oxidation

Ozonation Post-treatment Full-scale Full decolourisation: water Expensive: aldehydes formed

reuse

Fenton’s reagent Pre-treatment Several full-scale plant Full decolourisation

in South Africa

Photocatalysis Post-treatment Pilot-scale Near complete colour For final polishing only J

a

removal H

Electrolysis Pre-treatment Pilot-scale Full decolourisation Foaming: limited electrode life 2.

El