Page 172 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 172

Industrial waters 145

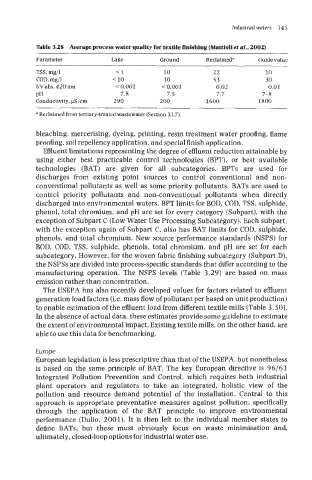

Table 3.28 Average process water quality for textile finishing (Mattioli et d., 2002)

Parameter Lake Ground Reclaimed" Guide value

TSS, mg/l <1 10 22 10

COD, mg/l < 10 30 53 30

W abs. 420 nm < 0.001 < 0.001 0.02 0.01

PH 7.8 7.5 7.7 7-8

Conductivity, pS/cm 290 200 1600 1800

a Reclaimed from tertiary-treated wastewater (Section 3.1.7).

bleaching, mercerising, dyeing, printing, resin treatment water proofing, flame

proofing, soil repellency application, and special finish application.

Effluent limitations representing the degree of effluent reduction attainable by

using either best practicable control technologies (BPT), or best available

technologies (BAT) are given for all subcategories. BPTs are used for

discharges from existing point sources to control conventional and non-

conventional pollutants as well as some priority pollutants. BATs are used to

control priority pollutants and non-conventional pollutants when directly

discharged into environmental waters. BPT limits for BOD, COD, TSS, sulphide,

phenol, total chromium, and pH are set for every category (Subpart), with the

exception of Subpart C (Low Water Use Processing Subcategory). Each subpart,

with the exception again of Subpart C, also has BAT limits for COD, sulphide,

phenols, and total chromium. New source performance standards (NSPS) for

BOD, COD, TSS, sulphide, phenols, total chromium, and pH are set for each

subcategory. However, for the woven fabric finishing subcategory (Subpart D),

the NSPSs are divided into process-specific standards that differ according to the

manufacturing operation. The NSPS levels (Table 3.29) are based on mass

emission rather than concentration.

The USEPA has also recently developed values for factors related to effluent

generation load factors (i.e. mass flow of pollutant per based on unit production)

to enable estimation of the effluent load from different textile mills (Table 3.30).

In the absence of actual data, these estimates provide some guideline to estimate

the extent of environmental impact. Existing textile mills, on the other hand, are

able to use this data for benchmarking.

Europe

European legislation is less prescriptive than that of the USEPA, but nonetheless

is based on the same principle of BAT. The key European directive is 96/61

Integrated Pollution Prevention and Control, which requires both industrial

plant operators and regulators to take an integrated, holistic view of the

pollution and resource demand potential of the installation. Central to this

approach is appropriate preventative measures against pollution, specifically

through the application of the BAT principle to improve environmental

performance (Dulio, 2001). It is then left to the individual member states to

define BATs, but these must obviously focus on waste minimisation and,

ultimately, closed-loop options for industrial water use.