Page 171 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 171

144 Membranes for Industrial Wastewater Recovery and Re-use

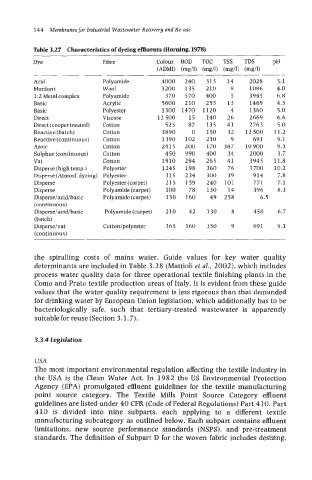

Table 3.27 Characteristics of dyeing effluents (Horning, 1978)

Dye Fibre Colour BOD TOC TSS TDS PH

(ADW (mg/l) (mg/l) (mg/U (mg/l)

Acid Polyamide 4000 240 315 14 2028 5.1

Mordant Wool 3200 135 210 9 1086 4.0

1:2 Metal complex Polyamide 3 70 5 70 400 5 3945 6.8

Basic Acrylic 5600 210 255 13 1469 4.5

Basic Polyester 1300 1470 1120 4 1360 5.0

Direct Viscose 12 500 15 140 26 2669 6.6

Direct (cooper treated) Cotton 525 87 135 41 2763 5.0

Reactive (batch) Cotton 3890 0 150 32 12500 11.2

Reactive (continuous) Cotton 1390 102 230 9 691 9.1

Azoic Cotton 2415 200 170 387 10900 9.3

Sulphur (continuous) Cotton 450 990 400 34 2000 3.7

Vat Cotton 1910 294 265 41 3945 11.8

Disperse (high temp.) Polyester 1245 198 360 76 1700 10.2

Disperse (Atmosf. dyeing) Polyester 315 234 300 39 914 7.8

Disperse Polyester (carpet) 215 159 240 101 771 7.1

Disperse Polyamide (carpet) 100 78 130 14 396 8.3

Disperse/acid/basic Polyamide (carpet) 130 160 49 258 6.5

(continuous)

Disperse/acid/basic Polyamide(carpet) 210 42 130 8 450 6.7

(batch)

Disperse/vat Cotton/polyester 365 360 350 9 691 9.1

(continuous)

the spiralling costs of mains water. Guide values for key water quality

determinants are included in Table 3.28 (Mattioli et al., 2002), which includes

process water quality data for three operational textile finishing plants in the

Como and Prato textile production areas of Italy. It is evident from these guide

values that the water quality requirement is less rigorous than that demanded

for drinking water by European Union legislation, which additionally has to be

bacteriologically safe, such that tertiary-treated wastewater is apparently

suitable for reuse (Section 3.1.7).

3.3.4 Legislation

USA

The most important environmental regulation affecting the textile industry in

the USA is the Clean Water Act. In 1982 the US Environmental Protection

Agency (EPA) promulgated effluent guidelines for the textile manufacturing

point source category. The Textile Mills Point Source Category effluent

guidelines are listed under 40 CFR (Code of Federal Regulations) Part 410. Part

410 is divided into nine subparts, each applying to a different textile

manufacturing subcategory as outlined below. Each subpart contains effluent

limitations, new source performance standards (NSPS), and pre-treatment

standards. The definition of Subpart D for the woven fabric includes desizing,