Page 87 - Membranes for Industrial Wastewater Recovery and Re-Use

P. 87

Membrane technology 67

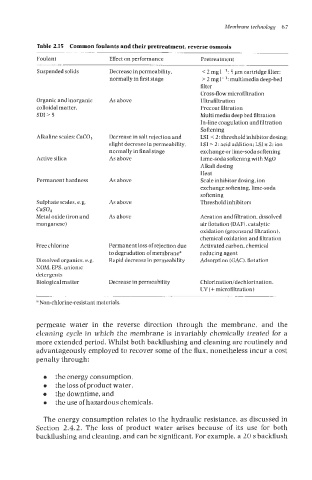

Table 2.15 Common foulants and their pretreatment, reverse osmosis

Foulant Effect on performance Pretreatment

~

Suspended solids Decrease in permeability, < 2 mg IF1: 5 pm cartridge filter;

normally in first stage > 2 mg I-': multimedia deep-bed

filter

Cross-flow microfiltration

Organic and inorganic As above Ultrafiltration

colloidal matter, Precoat filtration

SDI 5 Multimedia deep bed filtration

In-line coagulation and filtration

Softening

Alkaline scales: CaC03 Decrease in salt rejection and LSI < 2: threshold inhibitor dosing:

slight decrease in permeability, LSI > 2: acid addition: LSI n 2: ion

normally in ha1 stage exchange or lime-soda softening

Active silica As above Lime-soda softening with MgO

Alkali dosing

Heat

Permanent hardness As above Scale inhibitor dosing, ion

exchange softening, lime-soda

softening

Sulphate scales, e.g. As above Threshold inhibitors

CaS04

Metal oxide (iron and As above Aeration and filtration, dissolved

manganese) air flotation (DAF), catalytic

oxidation (greensand filtration),

chemical oxidation and filtration

Free chlorine Permanent loss of rejection due Activated carbon, chemical

to degradation ofmembrane" reducing agent

Dissolved organics. e.g. Rapid decrease in permeability Adsorption (GAC), flotation

NOM, EPS, anionic

detergents

Biological matter Decrease in permeability Chlorination/dechlorination.

UV (+ microfiltration)

a Non-chlorine-resistant materials.

permeate water in the reverse direction through the membrane, and the

cleaning cycle in which the membrane is invariably chemically treated for a

more extended period. Whilst both backflushing and cleaning are routinely and

advantageously employed to recover some of the flux, nonetheless incur a cost

penalty through:

a the energy consumption,

a the loss of product water,

a the downtime, and

a the use of hazardous chemicals.

The energy consumption relates to the hydraulic resistance, as discussed in

Section 2.4.2. The loss of product water arises because of its use for both

backflushing and cleaning, and can be significant. For example, a 20 s backflush