Page 136 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 136

1 18 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

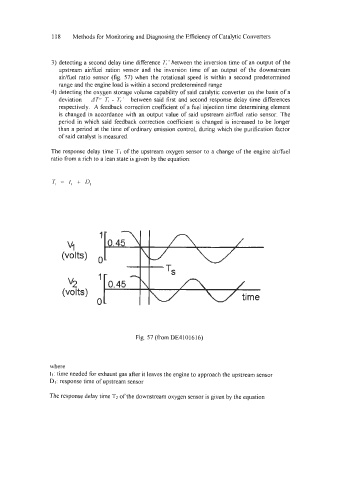

3) detecting a second delay time difference 7; ’ between the inversion time of an output of the

upstream air/fbel ration sensor and the inversion time of an output of the downstream

air/fbel ratio sensor (fig. 57) when the rotational speed is within a second predetermined

range and the engine load is within a second predetermined range

4) detecting the oxygen storage volume capability of said catalytic converter on the basis of a

deviation AT= T, - 7,’ between said first and second response delay time differences

respectively. A feedback correction coefficient of a fuel injection time determining element

is changed in accordance with an output value of said upstream air/fbel ratio sensor. The

period in which said feedback correction coefficient is changed is increased to be longer

than a period at the time of ordinary emission control, during which the purification factor

of said catalyst is measured.

The response delay time TI of the upstream oxygen sensor to a change of the engine air/fbel

ratio from a rich to a lean state is given by the equation:

7; = I, i- 13,

9

(volts)

v2

(volts)

Fig. 57 (from DE4101616)

where

tl: time needed for exhaust gas after it leaves the engine to approach the upstream sensor

DI: response time of upstream sensor

The response delay time Tz of the downstream oxygen sensor is given by the equation