Page 35 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 35

Introduction 17

the combustion chamber that does not allow the formation of NO,. Water also reduces the

flame temperature inside the diesel engine cylinder and contributes to reduction of NO,.

However, both methods complicate considerably the control of the engine and a lot of

additional components and instrumentation must be added to the engine system [33].

As already shown in Table 1, the main pollutant of diesel engines is the particulate matter

(soot). Particles are captured in filters or traps. The accumulated particulate raises filter

backpressure, i.e. the pressure difference across the filter or trap which is necessary to force

the exhaust through it. The filters are cleaned periodically by oxidizing the collected particulate

(regeneration of filter) to decrease the high backpressure. In modem diesel engines catalytic

coated filters and oxidation catalysts are used to eliminate particulate matter from the exhaust

gas.

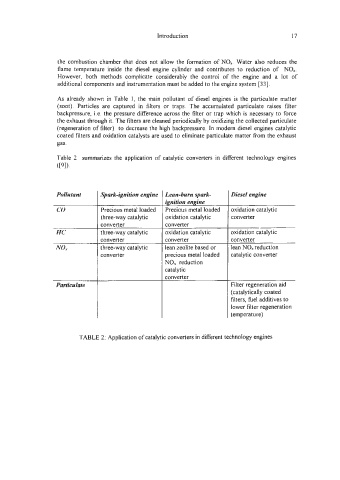

Table 2 summarizes the application of catalytic converters in different technology engines

..

([91).

Pdlutnnt 1 Spark-ignition engine Lean-burn spark- Diesel engine

ignition engine

co Precious metal loaded Precious metal loaded oxidation catalytic

three-way catalytic oxidation catalytic converter

converter converter

HC three-way catalytic oxidation catalytic oxidation catalytic

converter converter converter

NOx three-way catalytic lean zeolite based or lean NO, reduction

converter precious metal loaded catalytic converter

NO, reduction

catalytic

converter

Particulate Filter regeneration aid

(catalytically coated

filters, fuel additives to

lower filter regeneration

temperature)

TABLE 2: Application of catalytic converters in different technology engines