Page 79 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 79

Daimler-Benz AG 61

In GB2178857 (1987) another workshop test method is applied. At idling or fast idling

conditions, a forced switch of the engine airhe1 ratio fiom rich to lean and the opposite takes

place. By introducing a delay element (RC element or a low pass filter) in the control circuit of

the 1. probe located upstream of the catalytic converter, the switch is retarded by 10 to 5000

msec (preferably 50 to 200 msec). The amount of measured remaining combustible

constituents in the exhaust gases after the catalytic converter is a measure of its condition.

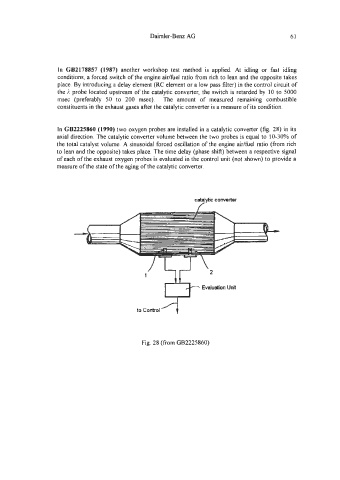

In GB2225860 (1990) two oxygen probes are installed in a catalytic converter (fig. 28) in its

axial direction. The catalytic converter volume between the two probes is equal to 10-30% of

the total catalyst volume. A sinusoidal forced oscillation of the engine aidfuel ratio (fiom rich

to lean and the opposite) takes place. The time delay (phase shift) between a respective signal

of each of the exhaust oxygen probes is evaluated in the control unit (not shown) to provide a

measure of the state of the aging of the catalytic converter.

catalytic converter

Evaluation Unit

Fig. 28 (from GB2225860)