Page 98 - Methods For Monitoring And Diagnosing The Efficiency Of Catalytic Converters A Patent - oriented Survey

P. 98

80 Methods for Monitoring and Diagnosing the Efficiency of Catalytic Converters

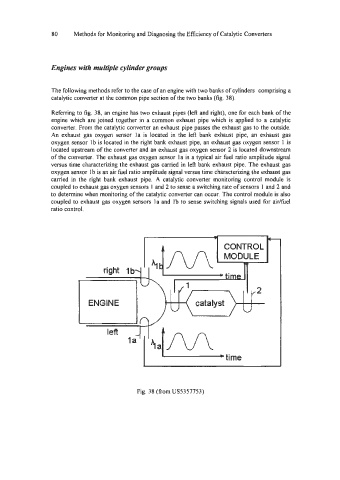

Engines with multiple cylinder groups

The following methods refer to the case of an engine with two banks of cylinders comprising a

catalytic converter at the common pipe section of the two banks (fig. 38).

Referring to fig. 38, an engine has two exhaust pipes (left and right), one for each bank of the

engine which are joined together in a common exhaust pipe which is applied to a catalytic

converter. From the catalytic converter an exhaust pipe passes the exhaust gas to the outside.

An exhaust gas oxygen sensor la is located in the left bank exhaust pipe, an exhaust gas

oxygen sensor Ib is located in the right bank exhaust pipe, an exhaust gas oxygen sensor 1 is

located upstream of the converter and an exhaust gas oxygen sensor 2 is located downstream

of the converter. The exhaust gas oxygen sensor la is a typical air fuel ratio amplitude signal

versus time characterizing the exhaust gas carried in let? bank exhaust pipe. The exhaust gas

oxygen sensor 1 b is an air fuel ratio amplitude signal versus time characterizing the exhaust gas

carried in the right bank exhaust pipe. A catalytic converter monitoring control module is

coupled to exhaust gas oxygen sensors 1 and 2 to sense a switching rate of sensors 1 and 2 and

to determine when monitoring of the catalytic converter can occur. The control module is also

coupled to exhaust gas oxygen sensors la and Ib to sense switching signals used for aidfuel

ratio control.

Fig. 38 (from US5357753)