Page 223 - A Practical Guide from Design Planning to Manufacturing

P. 223

196 Chapter Six

PS

PS 1 0

F-F

PS Tk NS 1 PS 1

0

Tk D Q Prd

PS Tk Clk

1

F-F

PS Tk NS 0 PS 0

0

PS 0 D Q

PS PS 0 Clk

1

Branch

Clock

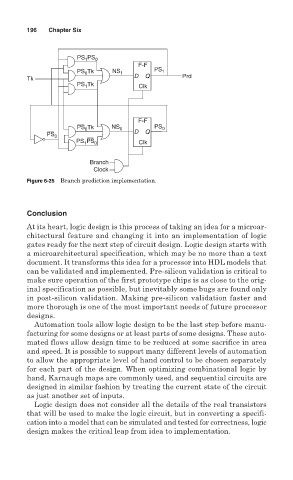

Figure 6-25 Branch prediction implementation.

Conclusion

At its heart, logic design is this process of taking an idea for a microar-

chitectural feature and changing it into an implementation of logic

gates ready for the next step of circuit design. Logic design starts with

a microarchitectural specification, which may be no more than a text

document. It transforms this idea for a processor into HDL models that

can be validated and implemented. Pre-silicon validation is critical to

make sure operation of the first prototype chips is as close to the orig-

inal specification as possible, but inevitably some bugs are found only

in post-silicon validation. Making pre-silicon validation faster and

more thorough is one of the most important needs of future processor

designs.

Automation tools allow logic design to be the last step before manu-

facturing for some designs or at least parts of some designs. These auto-

mated flows allow design time to be reduced at some sacrifice in area

and speed. It is possible to support many different levels of automation

to allow the appropriate level of hand control to be chosen separately

for each part of the design. When optimizing combinational logic by

hand, Karnaugh maps are commonly used, and sequential circuits are

designed in similar fashion by treating the current state of the circuit

as just another set of inputs.

Logic design does not consider all the details of the real transistors

that will be used to make the logic circuit, but in converting a specifi-

cation into a model that can be simulated and tested for correctness, logic

design makes the critical leap from idea to implementation.