Page 68 - MODELING OF ASPHALT CONCRETE

P. 68

46 Cha pte r T w o

∗

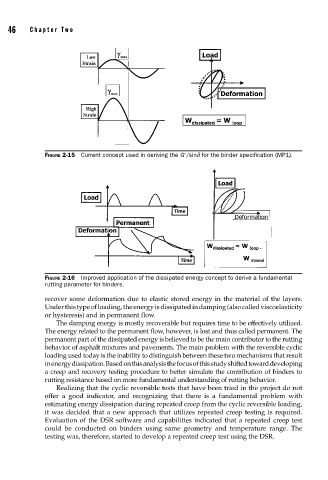

FIGURE 2-15 Current concept used in deriving the G /sind for the binder specifi cation (MP1).

FIGURE 2-16 Improved application of the dissipated energy concept to derive a fundamental

rutting parameter for binders.

recover some deformation due to elastic stored energy in the material of the layers.

Under this type of loading, the energy is dissipated in damping (also called viscoelasticity

or hysteresis) and in permanent flow.

The damping energy is mostly recoverable but requires time to be effectively utilized.

The energy related to the permanent flow, however, is lost and thus called permanent. The

permanent part of the dissipated energy is believed to be the main contributor to the rutting

behavior of asphalt mixtures and pavements. The main problem with the reversible cyclic

loading used today is the inability to distinguish between these two mechanisms that result

in energy dissipation. Based on this analysis the focus of this study shifted toward developing

a creep and recovery testing procedure to better simulate the contribution of binders to

rutting resistance based on more fundamental understanding of rutting behavior.

Realizing that the cyclic reversible tests that have been tried in the project do not

offer a good indicator, and recognizing that there is a fundamental problem with

estimating energy dissipation during repeated creep from the cyclic reversible loading,

it was decided that a new approach that utilizes repeated creep testing is required.

Evaluation of the DSR software and capabilities indicated that a repeated creep test

could be conducted on binders using same geometry and temperature range. The

testing was, therefore, started to develop a repeated creep test using the DSR.