Page 75 - MODELING OF ASPHALT CONCRETE

P. 75

Modeling of Asphalt Binder Rheology and Its Application to Modified Binders 53

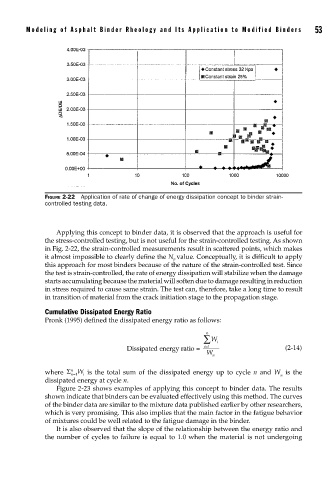

FIGURE 2-22 Application of rate of change of energy dissipation concept to binder strain-

controlled testing data.

Applying this concept to binder data, it is observed that the approach is useful for

the stress-controlled testing, but is not useful for the strain-controlled testing. As shown

in Fig. 2-22, the strain-controlled measurements result in scattered points, which makes

it almost impossible to clearly define the N value. Conceptually, it is difficult to apply

p

this approach for most binders because of the nature of the strain-controlled test. Since

the test is strain-controlled, the rate of energy dissipation will stabilize when the damage

starts accumulating because the material will soften due to damage resulting in reduction

in stress required to cause same strain. The test can, therefore, take a long time to result

in transition of material from the crack initiation stage to the propagation stage.

Cumulative Dissipated Energy Ratio

Pronk (1995) defined the dissipated energy ratio as follows:

n

∑ W i

Dissipated energy ratio = i=1 (2-14)

W

n

n

where Σ W is the total sum of the dissipated energy up to cycle n and W is the

n=1

i

n

dissipated energy at cycle n.

Figure 2-23 shows examples of applying this concept to binder data. The results

shown indicate that binders can be evaluated effectively using this method. The curves

of the binder data are similar to the mixture data published earlier by other researchers,

which is very promising. This also implies that the main factor in the fatigue behavior

of mixtures could be well related to the fatigue damage in the binder.

It is also observed that the slope of the relationship between the energy ratio and

the number of cycles to failure is equal to 1.0 when the material is not undergoing