Page 42 - Modular design for machine tools

P. 42

14 Modular Design Guide and Machine Tools Description

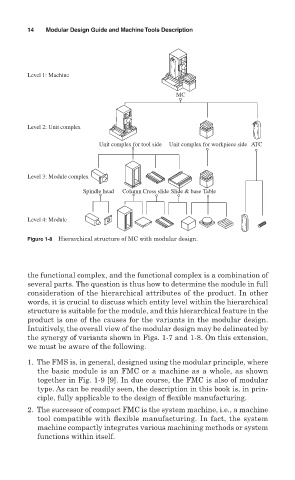

Level 1: Machine

MC

Level 2: Unit complex

Unit complex for tool side Unit complex for workpiece side ATC

Level 3: Module complex

Spindle head Column Cross slide Slide & base Table

Level 4: Module

Figure 1-8 Hierarchical structure of MC with modular design.

the functional complex, and the functional complex is a combination of

several parts. The question is thus how to determine the module in full

consideration of the hierarchical attributes of the product. In other

words, it is crucial to discuss which entity level within the hierarchical

structure is suitable for the module, and this hierarchical feature in the

product is one of the causes for the variants in the modular design.

Intuitively, the overall view of the modular design may be delineated by

the synergy of variants shown in Figs. 1-7 and 1-8. On this extension,

we must be aware of the following.

1. The FMS is, in general, designed using the modular principle, where

the basic module is an FMC or a machine as a whole, as shown

together in Fig. 1-9 [9]. In due course, the FMC is also of modular

type. As can be readily seen, the description in this book is, in prin-

ciple, fully applicable to the design of flexible manufacturing.

2. The successor of compact FMC is the system machine, i.e., a machine

tool compatible with flexible manufacturing. In fact, the system

machine compactly integrates various machining methods or system

functions within itself.