Page 45 - Modular design for machine tools

P. 45

16 Modular Design Guide and Machine Tools Description

Within a system machine context, the processing complex has been

on the market since the late 1990s, as already shown in Fig. 1-5, and

we must be aware that these cells and machines are of modular type.

It is especially emphasized that the processing complex is expected to

take over the role of the conventional MC and TC (turning center) of

present day to a larger extent, although forcing perhaps some marked

changes in the modular design (refer to Chap. 2).

Intuitively, an extreme problem in the processing complex lies in the

design of the structural body component (module), which must have

sufficient stiffness against all the resultant cutting forces loaded by

various machining methods. With respect to the planer and planomiller,

for example, the cross sections of their columns are, as widely known,

of narrower width and larger depth, and rectangular, respectively,

because the directions of the resultant cutting force are completely dif-

ferent from each other. As can be readily seen, the difficulty in design

increases duly in the case of the column of the planer with milling head.

The same scenario is a burning issue in designing the structural body

component, e.g., bed and headstock, of the processing complex. In accor-

dance with the experience so far, the processing complex shows very com-

plicated thermal behavior beyond the prediction of the machine tool

designer.

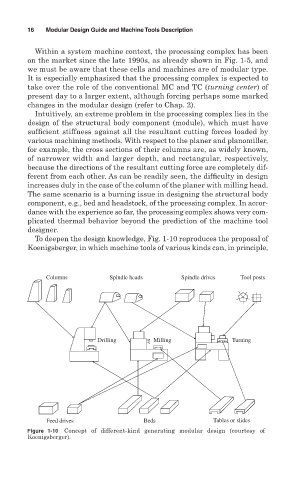

To deepen the design knowledge, Fig. 1-10 reproduces the proposal of

Koenigsberger, in which machine tools of various kinds can, in principle,

Columns Spindle heads Spindle drives Tool posts

Drilling Milling Turning

Feed drives Beds Tables or slides

Figure 1-10 Concept of different-kind generating modular design (courtesy of

Koenigsberger).