Page 50 - Modular design for machine tools

P. 50

Basic Knowledge: What Is the Modular Design? 21

Sublimation to

generalized

design technology

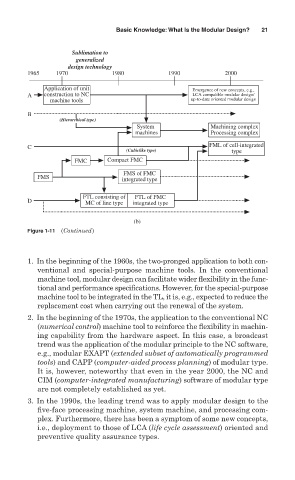

1965 1970 1980 1990 2000

Application of unit Emergence of new concepts, e.g.,

A construction to NC LCA compatible modular design/

machine tools up-to-date oriented modular design

B

(Hierarchical type)

System Machining complex

machines Processing complex

C FML of cell-integrated

(Cubiclike type) type

FMC Compact FMC

FMS of FMC

FMS integrated type

FTL consisting of FTL of FMC

D MC of line type integrated type

(b)

Figure 1-11 (Continued)

1. In the beginning of the 1960s, the two-pronged application to both con-

ventional and special-purpose machine tools. In the conventional

machine tool, modular design can facilitate wider flexibility in the func-

tional and performance specifications. However, for the special-purpose

machine tool to be integrated in the TL, it is, e.g., expected to reduce the

replacement cost when carrying out the renewal of the system.

2. In the beginning of the 1970s, the application to the conventional NC

(numerical control) machine tool to reinforce the flexibility in machin-

ing capability from the hardware aspect. In this case, a broadcast

trend was the application of the modular principle to the NC software,

e.g., modular EXAPT (extended subset of automatically programmed

tools) and CAPP (computer-aided process planning) of modular type.

It is, however, noteworthy that even in the year 2000, the NC and

CIM (computer-integrated manufacturing) software of modular type

are not completely established as yet.

3. In the 1990s, the leading trend was to apply modular design to the

five-face processing machine, system machine, and processing com-

plex. Furthermore, there has been a symptom of some new concepts,

i.e., deployment to those of LCA (life cycle assessment) oriented and

preventive quality assurance types.