Page 54 - Modular design for machine tools

P. 54

Basic Knowledge: What Is the Modular Design? 25

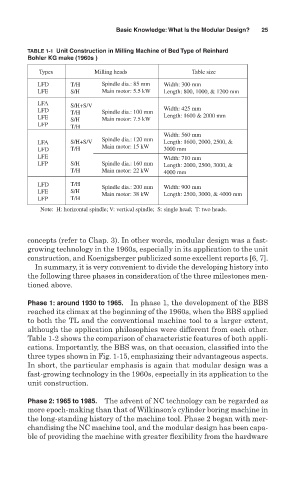

TABLE 1-1 Unit Construction in Milling Machine of Bed Type of Reinhard

Bohler KG make (1960s )

Types Milling heads Table size

LFD T/H Spindle dia.: 85 mm Width: 300 mm

LFE S/H Main motor: 5.5 kW Length: 800, 1000, & 1200 mm

LFA

S/H+S/V

LFD T/H Spindle dia.: 100 mm Width: 425 mm

LFE Length: 1600 & 2000 mm

S/H Main motor: 7.5 kW

LFP T/H

Width: 560 mm

Spindle dia.: 120 mm

LFA S/H+S/V Length: 1600, 2000, 2500, &

LFD T/H Main motor: 15 kW 3000 mm

LFE Width: 710 mm

LFP S/H Spindle dia.: 160 mm Length: 2000, 2500, 3000, &

T/H Main motor: 22 kW 4000 mm

LFD T/H Spindle dia.: 200 mm Width: 900 mm

LFE S/H Main motor: 38 kW Length: 2500, 3000, & 4000 mm

LFP T/H

Note: H: horizontal spindle; V: vertical spindle; S: single head; T: two heads.

concepts (refer to Chap. 3). In other words, modular design was a fast-

growing technology in the 1960s, especially in its application to the unit

construction, and Koenigsberger publicized some excellent reports [6, 7].

In summary, it is very convenient to divide the developing history into

the following three phases in consideration of the three milestones men-

tioned above.

Phase 1: around 1930 to 1965. In phase 1, the development of the BBS

reached its climax at the beginning of the 1960s, when the BBS applied

to both the TL and the conventional machine tool to a larger extent,

although the application philosophies were different from each other.

Table 1-2 shows the comparison of characteristic features of both appli-

cations. Importantly, the BBS was, on that occasion, classified into the

three types shown in Fig. 1-15, emphasizing their advantageous aspects.

In short, the particular emphasis is again that modular design was a

fast-growing technology in the 1960s, especially in its application to the

unit construction.

Phase 2: 1965 to 1985. The advent of NC technology can be regarded as

more epoch-making than that of Wilkinson’s cylinder boring machine in

the long-standing history of the machine tool. Phase 2 began with mer-

chandising the NC machine tool, and the modular design has been capa-

ble of providing the machine with greater flexibility from the hardware