Page 53 - Modular design for machine tools

P. 53

24 Modular Design Guide and Machine Tools Description

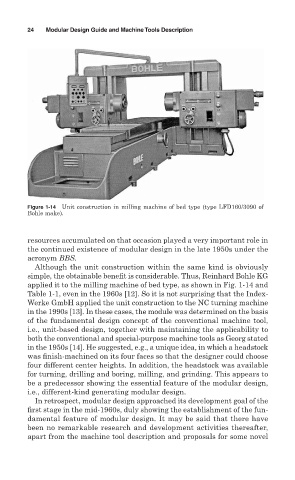

Figure 1-14 Unit construction in milling machine of bed type (type LFD160/3090 of

Bohle make).

resources accumulated on that occasion played a very important role in

the continued existence of modular design in the late 1950s under the

acronym BBS.

Although the unit construction within the same kind is obviously

simple, the obtainable benefit is considerable. Thus, Reinhard Bohle KG

applied it to the milling machine of bed type, as shown in Fig. 1-14 and

Table 1-1, even in the 1960s [12]. So it is not surprising that the Index-

Werke GmbH applied the unit construction to the NC turning machine

in the 1990s [13]. In these cases, the module was determined on the basis

of the fundamental design concept of the conventional machine tool,

i.e., unit-based design, together with maintaining the applicability to

both the conventional and special-purpose machine tools as Georg stated

in the 1950s [14]. He suggested, e.g., a unique idea, in which a headstock

was finish-machined on its four faces so that the designer could choose

four different center heights. In addition, the headstock was available

for turning, drilling and boring, milling, and grinding. This appears to

be a predecessor showing the essential feature of the modular design,

i.e., different-kind generating modular design.

In retrospect, modular design approached its development goal of the

first stage in the mid-1960s, duly showing the establishment of the fun-

damental feature of modular design. It may be said that there have

been no remarkable research and development activities thereafter,

apart from the machine tool description and proposals for some novel