Page 55 - Modular design for machine tools

P. 55

26 Modular Design Guide and Machine Tools Description

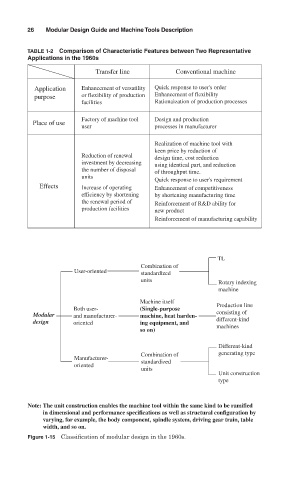

TABLE 1-2 Comparison of Characteristic Features between Two Representative

Applications in the 1960s

Transfer line Conventional machine

Application Enhancement of versatility Quick response to user's order

purpose or flexibility of production Enhancement of flexibility

facilities Rationaization of production processes

Factory of machine tool Design and production

Place of use

user processes in manufacturer

Realization of machine tool with

keen price by reduction of

Reduction of renewal design time, cost reduction

investment by decreasing using identical part, and reduction

the number of disposal of throughput time.

units

Quick response to user's requirement

Effects Increase of operating Enhancement of competitiveness

efficiency by shortening by shortening manufacturing time

the renewal period of Reinforcement of R&D ability for

production facilities new product

Reinforcement of manufacturing capability

TL

Combination of

User-oriented standardized

units

Rotary indexing

machine

Machine itself

Both user- (Single-purpose Production line

Modular and manufacturer- machine, heat harden- consisting of

design oriented ing equipment, and different-kind

so on) machines

Different-kind

Combination of generating type

Manufacturer- standardized

oriented

units

Unit construction

type

Note: The unit construction enables the machine tool within the same kind to be ramified

in dimensional and performance specifications as well as structural configuration by

varying, for example, the body component, spindle system, driving gear train, table

width, and so on.

Figure 1-15 Classification of modular design in the 1960s.