Page 52 - Modular design for machine tools

P. 52

Basic Knowledge: What Is the Modular Design? 23

Spindle Spindle head

head unit A unit A

Spindle head Spindle head

unit A unit A

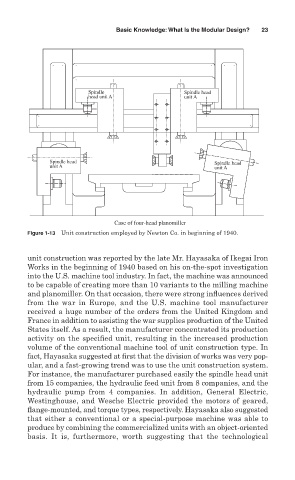

Case of four-head planomiller

Figure 1-13 Unit construction employed by Newton Co. in beginning of 1940.

unit construction was reported by the late Mr. Hayasaka of Ikegai Iron

Works in the beginning of 1940 based on his on-the-spot investigation

into the U.S. machine tool industry. In fact, the machine was announced

to be capable of creating more than 10 variants to the milling machine

and planomiller. On that occasion, there were strong influences derived

from the war in Europe, and the U.S. machine tool manufacturer

received a huge number of the orders from the United Kingdom and

France in addition to assisting the war supplies production of the United

States itself. As a result, the manufacturer concentrated its production

activity on the specified unit, resulting in the increased production

volume of the conventional machine tool of unit construction type. In

fact, Hayasaka suggested at first that the division of works was very pop-

ular, and a fast-growing trend was to use the unit construction system.

For instance, the manufacturer purchased easily the spindle head unit

from 15 companies, the hydraulic feed unit from 8 companies, and the

hydraulic pump from 4 companies. In addition, General Electric,

Westinghouse, and Wesche Electric provided the motors of geared,

flange-mounted, and torque types, respectively. Hayasaka also suggested

that either a conventional or a special-purpose machine was able to

produce by combining the commercialized units with an object-oriented

basis. It is, furthermore, worth suggesting that the technological