Page 69 - Modular design for machine tools

P. 69

Basic Knowledge: What Is the Modular Design? 39

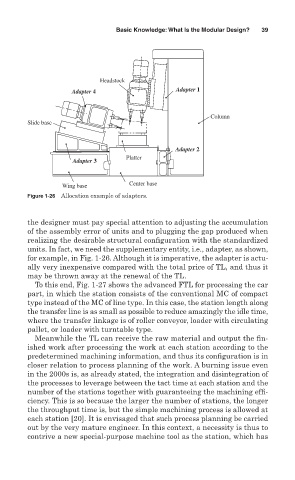

Headstock

Adapter 4 Adapter 1

Column

Slide base

Adapter 2

Platter

Adapter 3

Center base

Wing base

Figure 1-26 Allocation example of adapters.

the designer must pay special attention to adjusting the accumulation

of the assembly error of units and to plugging the gap produced when

realizing the desirable structural configuration with the standardized

units. In fact, we need the supplementary entity, i.e., adapter, as shown,

for example, in Fig. 1-26. Although it is imperative, the adapter is actu-

ally very inexpensive compared with the total price of TL, and thus it

may be thrown away at the renewal of the TL.

To this end, Fig. 1-27 shows the advanced FTL for processing the car

part, in which the station consists of the conventional MC of compact

type instead of the MC of line type. In this case, the station length along

the transfer line is as small as possible to reduce amazingly the idle time,

where the transfer linkage is of roller conveyor, loader with circulating

pallet, or loader with turntable type.

Meanwhile the TL can receive the raw material and output the fin-

ished work after processing the work at each station according to the

predetermined machining information, and thus its configuration is in

closer relation to process planning of the work. A burning issue even

in the 2000s is, as already stated, the integration and disintegration of

the processes to leverage between the tact time at each station and the

number of the stations together with guaranteeing the machining effi-

ciency. This is so because the larger the number of stations, the longer

the throughput time is, but the simple machining process is allowed at

each station [20]. It is envisaged that such process planning be carried

out by the very mature engineer. In this context, a necessity is thus to

contrive a new special-purpose machine tool as the station, which has