Page 70 - Modular design for machine tools

P. 70

40 Modular Design Guide and Machine Tools Description

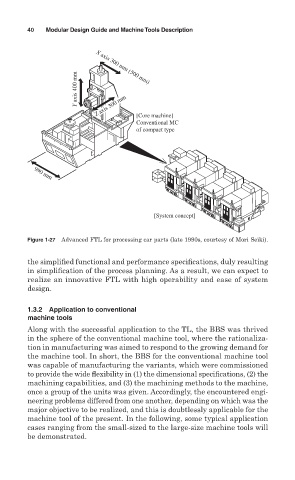

Y axis 400 mm X axis 300 mm (500 mm)

Z axis 300 mm

[Core machine]

Conventional MC

of compact type

990 mm

[System concept]

Figure 1-27 Advanced FTL for processing car parts (late 1990s, courtesy of Mori Seiki).

the simplified functional and performance specifications, duly resulting

in simplification of the process planning. As a result, we can expect to

realize an innovative FTL with high operability and ease of system

design.

1.3.2 Application to conventional

machine tools

Along with the successful application to the TL, the BBS was thrived

in the sphere of the conventional machine tool, where the rationaliza-

tion in manufacturing was aimed to respond to the growing demand for

the machine tool. In short, the BBS for the conventional machine tool

was capable of manufacturing the variants, which were commissioned

to provide the wide flexibility in (1) the dimensional specifications, (2) the

machining capabilities, and (3) the machining methods to the machine,

once a group of the units was given. Accordingly, the encountered engi-

neering problems differed from one another, depending on which was the

major objective to be realized, and this is doubtlessly applicable for the

machine tool of the present. In the following, some typical application

cases ranging from the small-sized to the large-size machine tools will

be demonstrated.