Page 391 - Multidimensional Chromatography

P. 391

Multidimensional Chromatographic Applications in the Oil Industry 383

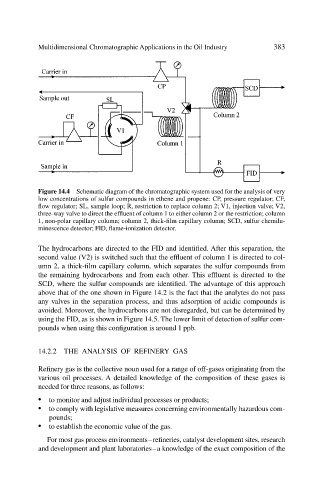

Figure 14.4 Schematic diagram of the chromatographic system used for the analysis of very

low concentrations of sulfur compounds in ethene and propene: CP, pressure regulator; CF,

flow regulator; SL, sample loop; R, restriction to replace column 2; V1, injection valve; V2,

three-way valve to direct the effluent of column 1 to either column 2 or the restriction; column

1, non-polar capillary column; column 2, thick-film capillary column; SCD, sulfur chemilu-

minescence detector; FID, flame-ionization detector.

The hydrocarbons are directed to the FID and identified. After this separation, the

second value (V2) is switched such that the effluent of column 1 is directed to col-

umn 2, a thick-film capillary column, which separates the sulfur compounds from

the remaining hydrocarbons and from each other. This effluent is directed to the

SCD, where the sulfur compounds are identified. The advantage of this approach

above that of the one shown in Figure 14.2 is the fact that the analytes do not pass

any valves in the separation process, and thus adsorption of acidic compounds is

avoided. Moreover, the hydrocarbons are not disregarded, but can be determined by

using the FID, as is shown in Figure 14.5. The lower limit of detection of sulfur com-

pounds when using this configuration is around 1 ppb.

14.2.2 THE ANALYSIS OF REFINERY GAS

Refinery gas is the collective noun used for a range of off-gases originating from the

various oil processes. A detailed knowledge of the composition of these gases is

needed for three reasons, as follows:

• to monitor and adjust individual processes or products;

• to comply with legislative measures concerning environmentally hazardous com-

pounds;

• to establish the economic value of the gas.

For most gas process environments–refineries, catalyst development sites, research

and development and plant laboratories–a knowledge of the exact composition of the