Page 393 - Multidimensional Chromatography

P. 393

Multidimensional Chromatographic Applications in the Oil Industry 385

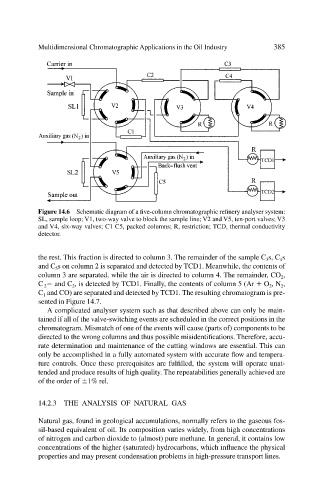

Figure 14.6 Schematic diagram of a five-column chromatographic refinery analyser system:

SL, sample loop; V1, two-way valve to block the sample line; V2 and V5, ten-port valves; V3

and V4, six-way valves; C1 C5, packed columns; R, restriction; TCD, thermal conductivity

detector.

the rest. This fraction is directed to column 3. The remainder of the sample C 3 s, C 4 s

and C 5 s on column 2 is separated and detected by TCD1. Meanwhile, the contents of

column 3 are separated, while the air is directed to column 4. The remainder, CO 2 ,

C 2 and C 2 , is detected by TCD1. Finally, the contents of column 5 (Ar O 2 ,N 2 ,

C 1 and CO) are separated and detected by TCD1. The resulting chromatogram is pre-

sented in Figure 14.7.

A complicated analyser system such as that described above can only be main-

tained if all of the valve-switching events are scheduled in the correct positions in the

chromatogram. Mismatch of one of the events will cause (parts of) components to be

directed to the wrong columns and thus possible misidentifications. Therefore, accu-

rate determination and maintenance of the cutting windows are essential. This can

only be accomplished in a fully automated system with accurate flow and tempera-

ture controls. Once these prerequisites are fulfilled, the system will operate unat-

tended and produce results of high quality. The repeatabilities generally achieved are

of the order of 1% rel.

14.2.3 THE ANALYSIS OF NATURAL GAS

Natural gas, found in geological accumulations, normally refers to the gaseous fos-

sil-based equivalent of oil. Its composition varies widely, from high concentrations

of nitrogen and carbon dioxide to (almost) pure methane. In general, it contains low

concentrations of the higher (saturated) hydrocarbons, which influence the physical

properties and may present condensation problems in high-pressure transport lines.